Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in Modern Industry”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in Modern Industry”

In the fast-paced world of pharmaceutical production, the use of advanced machinery has become increasingly vital to ensure efficiency, accuracy, and cost-effectiveness. Among the key machines that play a significant role in this process are table press machines and capsule filling machines, with TDP (Tablet Compression Machine) and THDP (Capsule Filling Machine) being two commonly used types.

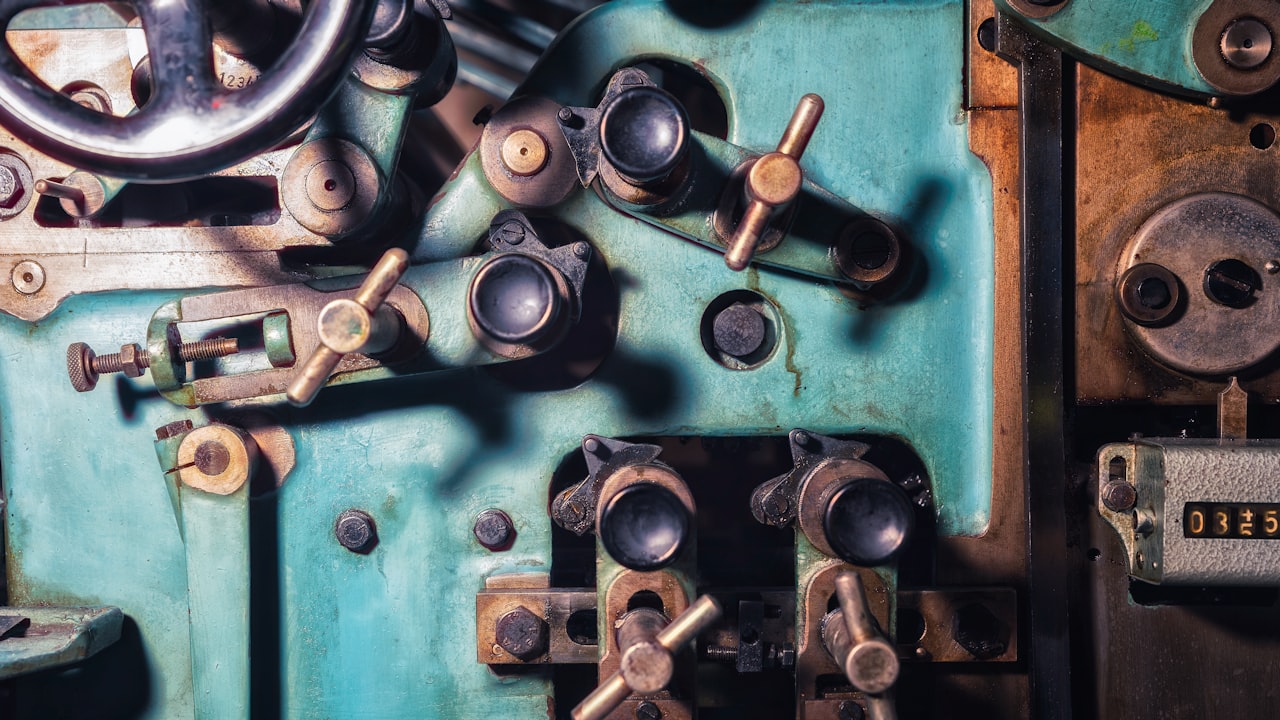

Tablet press machines, such as the TDP series, are instrumental in the manufacturing of tablets. These machines work by compressing powdered ingredients into tablet form, ensuring precise dosage and consistency. The TDP machines come in various models, ranging from single punch to rotary tablet presses, catering to different production requirements. With features like adjustable compression force and tooling options, TDP machines offer flexibility and reliability in the tablet manufacturing process.

On the other hand, capsule filling machines, like the THDP series, are designed to automate the filling of capsules with powder, pellets, or granules. THDP machines can fill a large number of capsules quickly and accurately, reducing the risk of human error and ensuring uniformity in dosage. The machines can handle different capsule sizes and are equipped with systems to control fill weight and detect empty capsules, optimizing productivity and quality control in the manufacturing process.

The integration of advanced technologies, such as servo motors and touch screen interfaces, in table press and capsule filling machines has further enhanced their performance capabilities. These technologies enable operators to monitor and adjust machine parameters with precision, leading to improved efficiency and reduced downtime. Additionally, the automation features of these machines streamline the production process, allowing for higher throughput and greater consistency in product quality.

In conclusion, the role of pharmaceutical machinery, particularly table press and capsule filling machines like TDP and THDP, cannot be understated in modern industry. These machines contribute significantly to the optimization of pharmaceutical production by ensuring accuracy, reliability, and efficiency. As technology continues to advance, the pharmaceutical industry will rely more heavily on innovative machinery to meet the growing demands for quality pharmaceutical products.