Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

In the dynamic landscape of the pharmaceutical industry, the utilization of advanced machinery has proven to be a pivotal factor in enhancing efficiency and ensuring precision in drug manufacturing processes. Among the array of innovative pharmaceutical machinery, table press machines and capsule filling machines play crucial roles in pharmaceutical production. This article will delve into the significance of these machines, with a focus on the popular TDP (Tablet Press) and THDP (Tablet Hardness Tester) models.

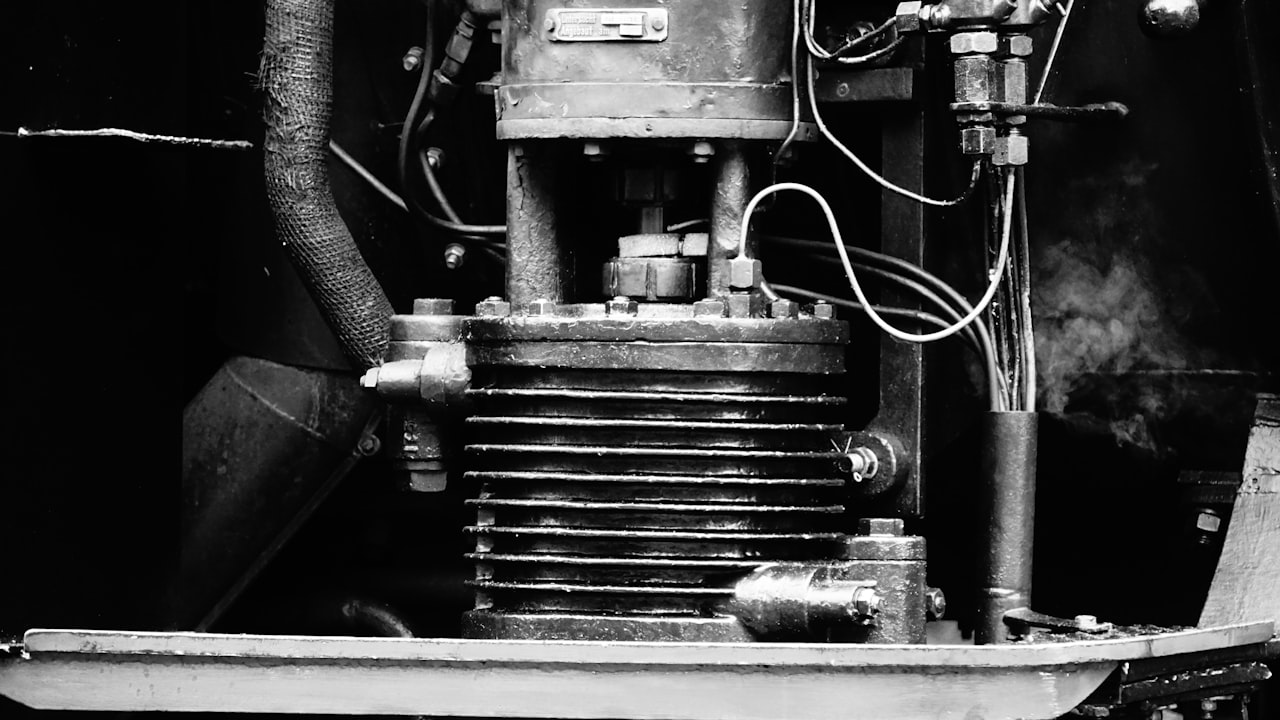

Tablet press machines, commonly referred to as tableting machines, are essential in the production of tablets and pills. These machines exert high pressure to compress powdered ingredients into precise and uniform tablets of varying shapes and sizes. The TDP series of tablet presses are renowned for their reliability and productivity in pharmaceutical manufacturing. With features such as adjustable compression force and multi-layer tablet capabilities, TDP machines offer versatility and consistency in tablet production processes. Pharmaceutical companies rely on TDP machines to meet the high demands of mass tablet production while maintaining quality standards.

In parallel, capsule filling machines stand out as indispensable equipment in encapsulation processes. These machines automate the filling of empty capsules with accurate dosages of powdered or granulated medications. By streamlining the encapsulation process, capsule filling machines ensure dosage precision and minimize variability in drug formulations. Pharmaceutical manufacturers benefit from the efficiency of capsule filling machines, such as reducing production time and minimizing material wastage. The integration of advanced technologies in modern capsule fillers, including automatic capsule orientation and dosage adjustment, has further optimized pharmaceutical production processes.

Moreover, the advent of innovative pharmaceutical machinery has introduced enhanced capabilities in tablet production and quality control. The THDP models, or Tablet Hardness Testers, are instrumental in evaluating the mechanical strength and durability of tablets. These machines measure the hardness of tablets by applying controlled pressure, allowing manufacturers to assess the integrity and disintegration properties of the tablets. The data obtained from THDP machines enable pharmaceutical companies to optimize formulations, identify potential quality issues, and ensure compliance with regulatory standards.

In conclusion, the evolution of pharmaceutical machinery, particularly table press machines and capsule filling machines, has revolutionized pharmaceutical production processes. The integration of advanced technologies such as TDP and THDP models has enhanced the precision, efficiency, and quality control in drug manufacturing. As pharmaceutical companies strive for innovation and compliance with stringent regulations, investing in state-of-the-art pharmaceutical machinery remains a cornerstone of success in the competitive pharmaceutical landscape.