Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”

In the realm of modern medicine manufacturing, the utilization of advanced pharmaceutical machinery has become indispensable. Two key pieces of equipment that play a crucial role in this process are the table press machine and the capsule filling machine. These machines, such as the TDP and THDP models, have revolutionized the pharmaceutical industry by streamlining production processes and ensuring the quality and consistency of medicinal products.

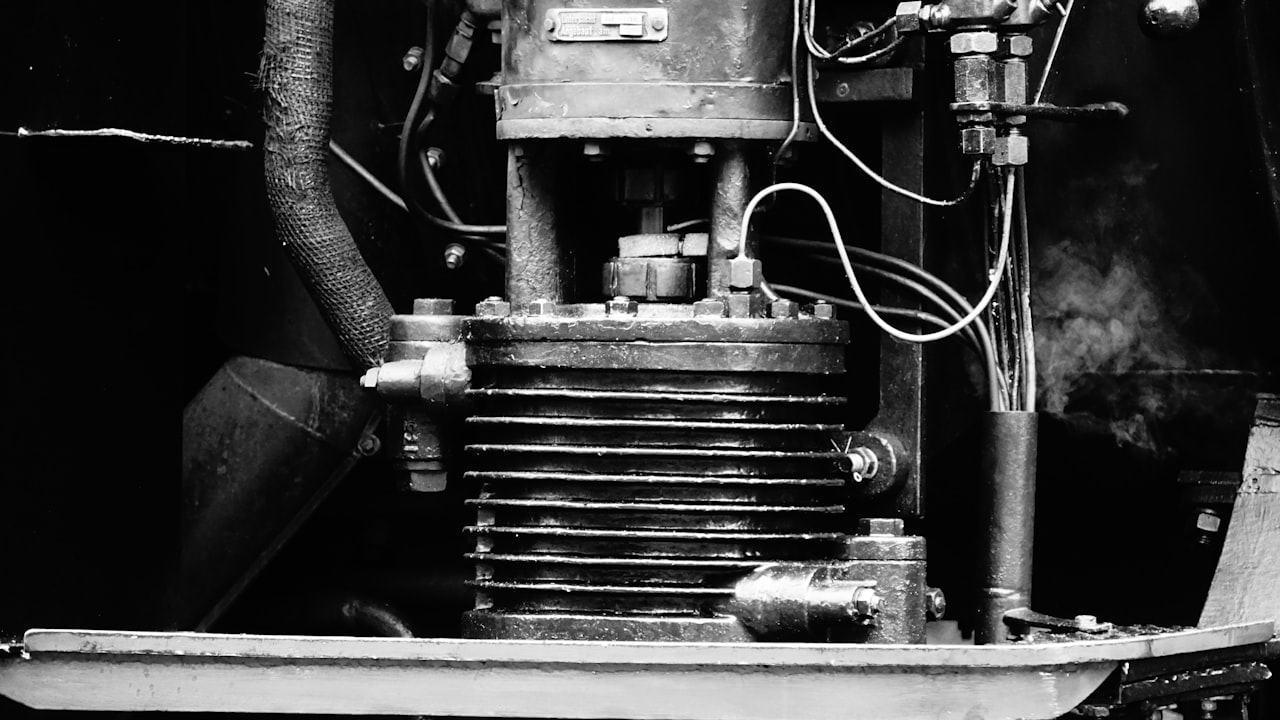

The table press machine, including the popular TDP model, is essential in the manufacturing of solid dosage forms such as tablets. This machine exerts pressure on powdered ingredients to form compact tablets of uniform size and density. With precise control over parameters such as compression force and dwell time, the table press machine can produce tablets with consistent quality and potency, meeting the strict standards of the pharmaceutical industry.

On the other hand, the capsule filling machine, exemplified by models like the THDP, is instrumental in the encapsulation of powdered or liquid medications. This machine automates the filling and sealing of capsules, ensuring accurate dosing and reducing the risk of contamination. By using the capsule filling machine, pharmaceutical manufacturers can enhance production efficiency and maintain the integrity of their products.

The TDP and THDP machines, along with other pharmaceutical machinery, offer numerous advantages in medicine manufacturing. Firstly, these machines enable high-speed production, allowing for large quantities of medicines to be manufactured in a relatively short period of time. This scalability is crucial in meeting the demands of a growing population and ensuring a stable supply of essential medications.

Secondly, pharmaceutical machinery such as the table press and capsule filling machines enhance product quality and consistency. By controlling critical manufacturing parameters, these machines reduce the risk of errors and variations in dosage, ensuring that each tablet or capsule meets the required specifications. This level of precision is essential in guaranteeing the safety and efficacy of pharmaceutical products.

Lastly, the use of advanced pharmaceutical machinery contributes to cost-effective manufacturing processes. By automating repetitive tasks and minimizing human intervention, these machines help reduce labor costs and improve production efficiency. Additionally, the ability to monitor and adjust parameters in real time enhances process visibility and control, leading to optimized production outcomes.

In conclusion, the table press machine, capsule filling machine, and other pharmaceutical machinery play a vital role in modern medicine manufacturing. These advanced tools enable pharmaceutical manufacturers to produce high-quality medicines efficiently and consistently, meeting the stringent requirements of the industry. As technology continues to advance, the integration of innovative machinery will further enhance the production of safe and effective medications for global healthcare needs.