Title: “The Evolution of Pharmaceutical Machinery: A Comprehensive Overview”

Title: “The Evolution of Pharmaceutical Machinery: A Comprehensive Overview”

Pharmaceutical machinery plays a crucial role in the manufacturing process of medicines, ensuring accuracy, efficiency, and quality in production. Over the years, advancements in technology have led to the evolution of pharmaceutical machinery, with significant improvements in processes such as tablet pressing and capsule filling. In this article, we will delve into the history and development of key machines in the pharmaceutical industry, including the table press machine, capsule filling machine, and the evolution from TDP to THDP.

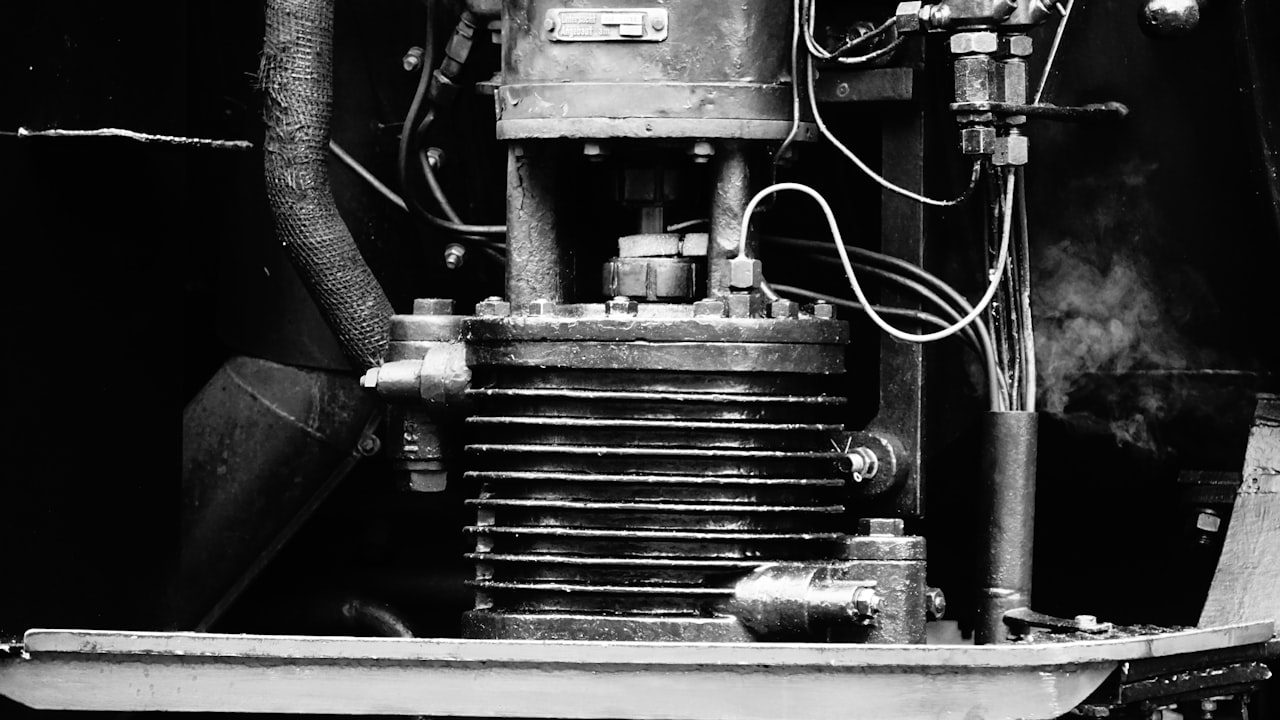

The table press machine, also known as a tablet press, is an essential piece of equipment used in the pharmaceutical industry to compress powdered or granular materials into tablets of uniform size and shape. The development of table press machines has significantly improved the efficiency and accuracy of tablet production. Early table press machines required manual operation, limiting the output and consistency of tablets. However, with technological advancements, modern table press machines are automated, with features such as precise weight control and speed adjustment, leading to higher productivity and quality control.

Similarly, capsule filling machines have undergone significant advancements in recent years. These machines are used to fill empty capsule shells with pharmaceutical powders or granules. With the evolution of capsule filling machines, pharmaceutical companies have been able to increase production capacity and enhance the accuracy of dosage formulations. Modern capsule filling machines are equipped with features such as automatic filling, sorting, and sealing, resulting in faster production speeds and reduced human error.

One of the notable advancements in pharmaceutical machinery is the transition from TDP (Tablet Press) machines to THDP (Touch Controlled High-Speed Tablet Press) machines. TDP machines were traditional machines that required manual operation and had limited production capabilities. However, with the introduction of THDP machines, pharmaceutical manufacturers gained access to high-speed production, improved efficiency, and greater control over the tablet pressing process. THDP machines are equipped with touch screen controls, data recording capabilities, and automatic monitoring systems, allowing for real-time adjustments and quality assurance in tablet production.

In conclusion, the evolution of pharmaceutical machinery, including table press machines, capsule filling machines, and the transition from TDP to THDP machines, has revolutionized the pharmaceutical manufacturing process. These advancements have led to increased efficiency, accuracy, and quality control in the production of medicines, ultimately benefiting both pharmaceutical companies and consumers. As technology continues to advance, the future of pharmaceutical machinery holds even more possibilities for innovation and improvement in the industry.