Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”

The pharmaceutical industry has undergone significant transformations in recent years, with technological advancements in pharmaceutical machinery playing a pivotal role in this evolution. From table press machines to capsule filling equipment, the introduction of cutting-edge technologies such as TDP (Tablet Press) and THDP (High-Speed Tablet Press) has revolutionized drug manufacturing processes.

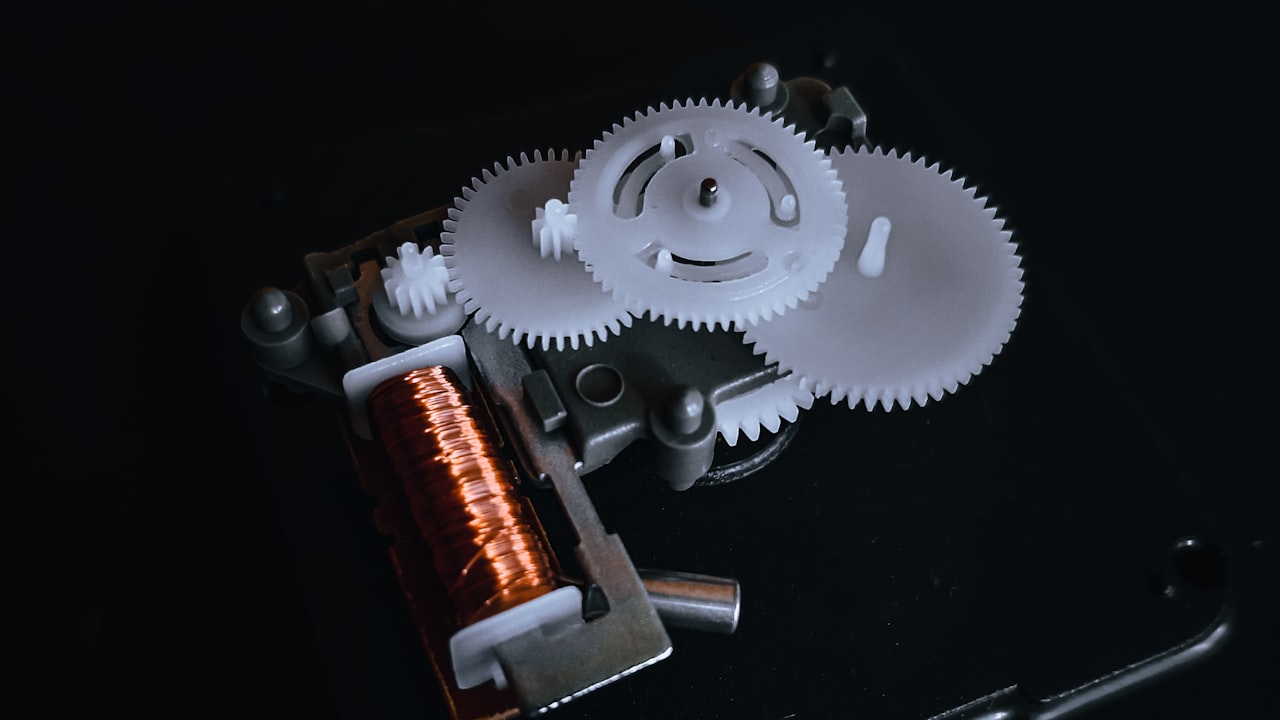

Table press machines, also known as tablet presses, are essential in the pharmaceutical industry for the production of solid dosage forms such as tablets and pills. These machines exert high pressure on powders or granules to form tablets of precise sizes and shapes. With the integration of automation and digital controls, modern table press machines ensure consistent tablet quality, reduce production time, and minimize material wastage.

Similarly, capsule filling machines have transformed the production of encapsulated medications. These machines automate the process of filling empty capsules with active pharmaceutical ingredients (APIs) or powders. By enhancing accuracy and efficiency, capsule filling machines enable pharmaceutical companies to meet growing demand while maintaining product quality and safety standards.

The introduction of advanced technologies such as TDP and THDP has further elevated the capabilities of pharmaceutical machinery. TDP machines, known for their high speed and precision, are capable of producing a large number of tablets per minute. This accelerated production rate not only increases efficiency but also allows manufacturers to quickly respond to market demands and regulatory requirements.

On the other hand, THDP machines, also referred to as high-speed tablet presses, offer superior performance in terms of output and quality. With features such as automatic weight control and real-time monitoring, THDP machines ensure consistent tablet properties and minimize variations in dosage. These advancements have positioned THDP machines as indispensable tools in modern pharmaceutical manufacturing facilities.

In conclusion, pharmaceutical machinery, including table press machines, capsule filling equipment, TDP, and THDP, plays a crucial role in revolutionizing the pharmaceutical industry. By embracing technological innovations and automation, manufacturers can enhance productivity, reduce costs, and accelerate drug development processes. As the industry continues to evolve, the integration of advanced pharmaceutical machinery will be essential in meeting the ever-increasing demands for safe, effective, and high-quality medications.

Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Industry

Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Industry Title: “Revolutionizing Pharmaceutical Manufacturing: The Impact of Pharmaceutical Machinery on Drug Production”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Impact of Pharmaceutical Machinery on Drug Production” Title: The Advancements of Pharmaceutical Machinery in the 21st Century

Title: The Advancements of Pharmaceutical Machinery in the 21st Century Title: The Evolution of Pharmaceutical Machinery: A Comprehensive Overview

Title: The Evolution of Pharmaceutical Machinery: A Comprehensive Overview Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”