Title: “Revolutionizing Pharmaceutical Manufacturing: The Impact of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Impact of Pharmaceutical Machinery”

Pharmaceutical manufacturing has undergone a significant transformation in recent years due to advancements in technology and the introduction of state-of-the-art machinery. Among the key players in this revolution are table press machines, capsule filling machines, as well as the innovative TDP and THDP models.

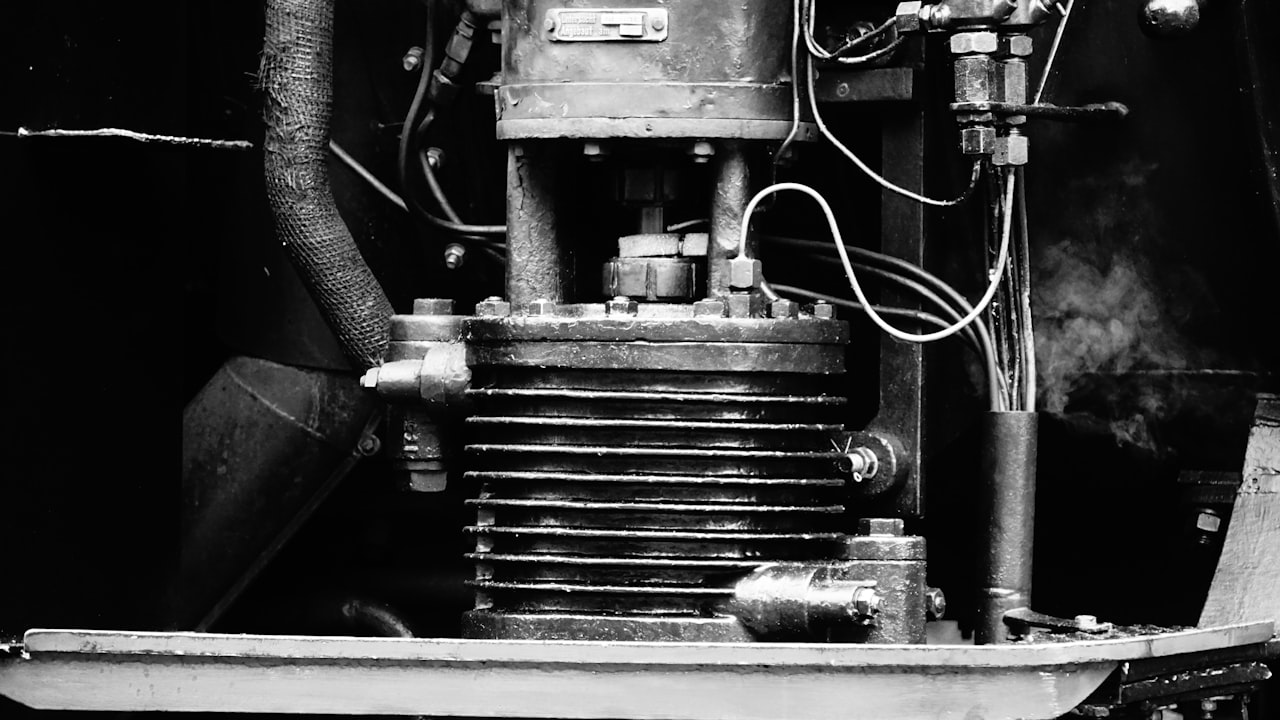

Table press machines are vital components in the production of pharmaceutical tablets. These machines use mechanical or hydraulic pressure to compress powdered ingredients into solid dosage forms. With precise control over parameters such as compression force and tablet thickness, table press machines ensure uniformity and consistency in tablet production. The latest models are equipped with advanced features like automatic feeding systems and real-time monitoring capabilities, enhancing efficiency and quality control in pharmaceutical manufacturing processes.

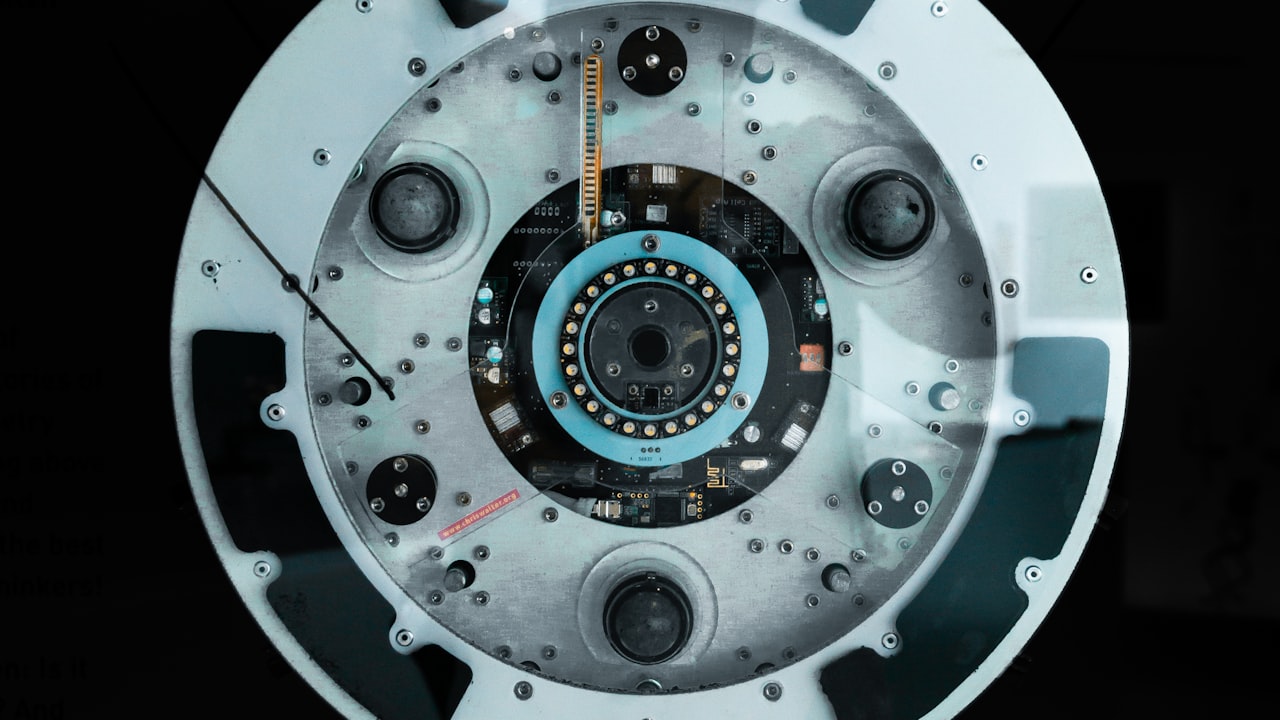

Capsule filling machines have also played a crucial role in streamlining pharmaceutical production. These machines automate the filling of empty capsule shells with powder, pellets, or liquid formulations. By significantly reducing manual labor and increasing filling accuracy, capsule filling machines not only improve production efficiency but also minimize the risk of dosage variations. Some modern capsule filling machines feature customizable filling options, allowing pharmaceutical manufacturers to cater to diverse market demands and dosage requirements.

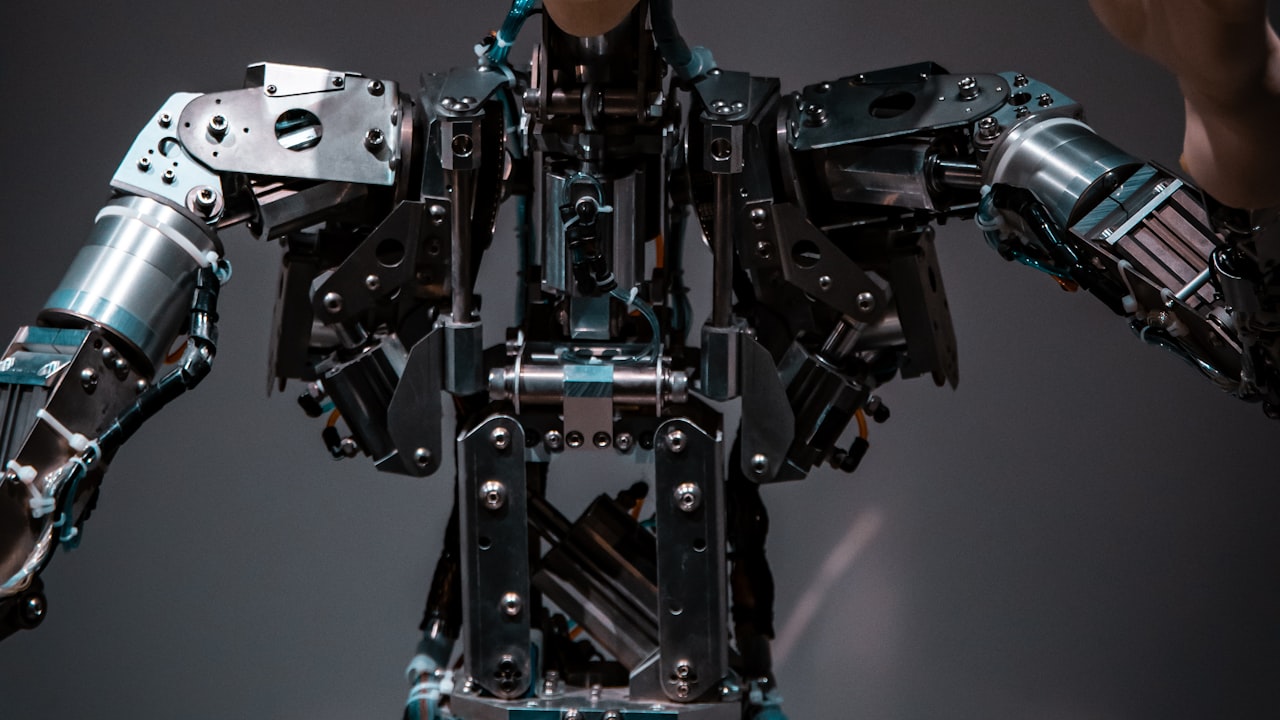

The introduction of the TDP (Tablet Pressing Machine) and THDP (Tablet Pressing Machine with Turret Heads) models has further revolutionized pharmaceutical manufacturing. TDP machines are compact and versatile, making them ideal for small-scale production or laboratory use. On the other hand, THDP machines are designed for high-volume production, with multiple turret heads enabling simultaneous tablet compression. These machines offer flexibility, speed, and precision, empowering pharmaceutical companies to meet growing demand while maintaining product quality and consistency.

In conclusion, the advent of sophisticated pharmaceutical machinery such as table press machines, capsule filling machines, TDP, and THDP models has transformed the landscape of pharmaceutical manufacturing. By enhancing efficiency, precision, and versatility, these machines have not only optimized production processes but also elevated quality standards in the pharmaceutical industry. As technology continues to advance, we can expect further innovations in pharmaceutical machinery that will drive the industry forward and shape the future of healthcare.

Title: “The Revolution of Pharmaceutical Machinery: Enhancing Drug Production Efficiency”

Title: “The Revolution of Pharmaceutical Machinery: Enhancing Drug Production Efficiency” Title: **Revolutionizing Medicine: The Role of Pharmaceutical Machinery in Drug Production**

Title: **Revolutionizing Medicine: The Role of Pharmaceutical Machinery in Drug Production** Title: “The Evolution of Pharmaceutical Machinery: Advancements in Drug Manufacturing Equipment”

Title: “The Evolution of Pharmaceutical Machinery: Advancements in Drug Manufacturing Equipment” Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery” Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery in the Industry”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery in the Industry” Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery” Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery” Title: The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing Processes

Title: The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing Processes