Title: “The Evolution of Pharmaceutical Machinery: Driving Innovation in Drug Manufacturing”

Title: “The Evolution of Pharmaceutical Machinery: Driving Innovation in Drug Manufacturing”

Pharmaceutical machinery has played a crucial role in the advancement of the drug manufacturing industry. From the early days of manual processes to the modern, automated equipment used today, the evolution of pharmaceutical machinery has greatly enhanced efficiency, accuracy, and overall productivity in drug manufacturing.

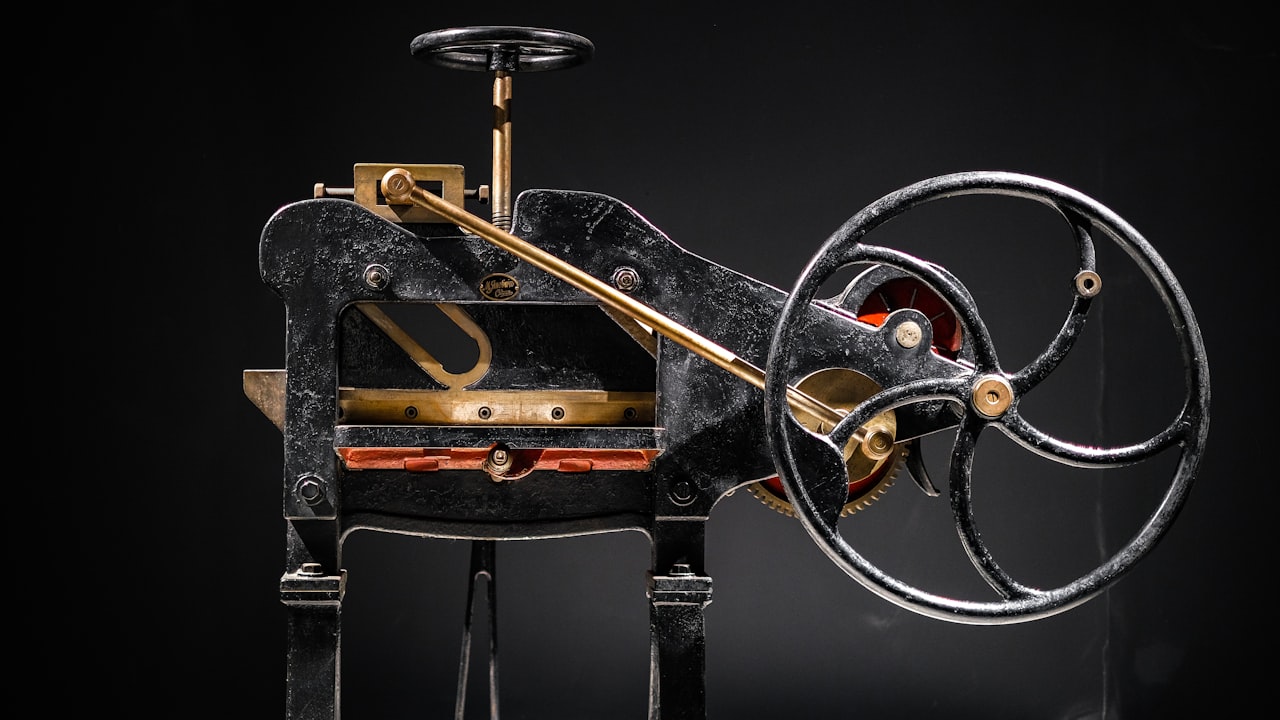

One of the key pieces of equipment in pharmaceutical manufacturing is the table press machine. This machine is essential for producing solid dosage forms such as tablets and pills. The table press machine compacts the powdered drug formulation into a specific shape and size, ensuring uniformity and dose consistency. Over the years, the table press machine has undergone significant improvements, from manual operation to fully automated systems that can produce thousands of tablets per hour with precise control over parameters such as compression force and tablet hardness.

Another important machine in pharmaceutical manufacturing is the capsule filling machine. This machine is used to fill empty capsules with the desired drug formulation, providing an alternative dosage form for patients who have difficulty swallowing tablets. Capsule filling machines come in various types, including manual, semi-automatic, and fully automatic models. Modern capsule filling machines can achieve high filling accuracy while minimizing wastage and ensuring product quality.

Two common types of table press machines used in pharmaceutical manufacturing are TDP (Tablet Press) and THDP (Tablet Hardness Tester). TDP machines are versatile and widely used for small to medium scale tablet production. They offer features such as adjustable compression force and tablet thickness, making them suitable for a wide range of formulations. On the other hand, THDP machines play a crucial role in ensuring the quality of tablets by measuring their hardness, which impacts factors like disintegration and dissolution rates.

In conclusion, the evolution of pharmaceutical machinery, including advancements in table press machines, capsule filling machines, TDP, and THDP equipment, has revolutionized drug manufacturing processes. These machines have not only improved production efficiency but also enhanced product quality and consistency. As technology continues to advance, we can expect even more sophisticated pharmaceutical machinery that will further drive innovation in drug manufacturing, ultimately benefiting patients and the healthcare industry as a whole.

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”