Title:

Title:

“Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Article:

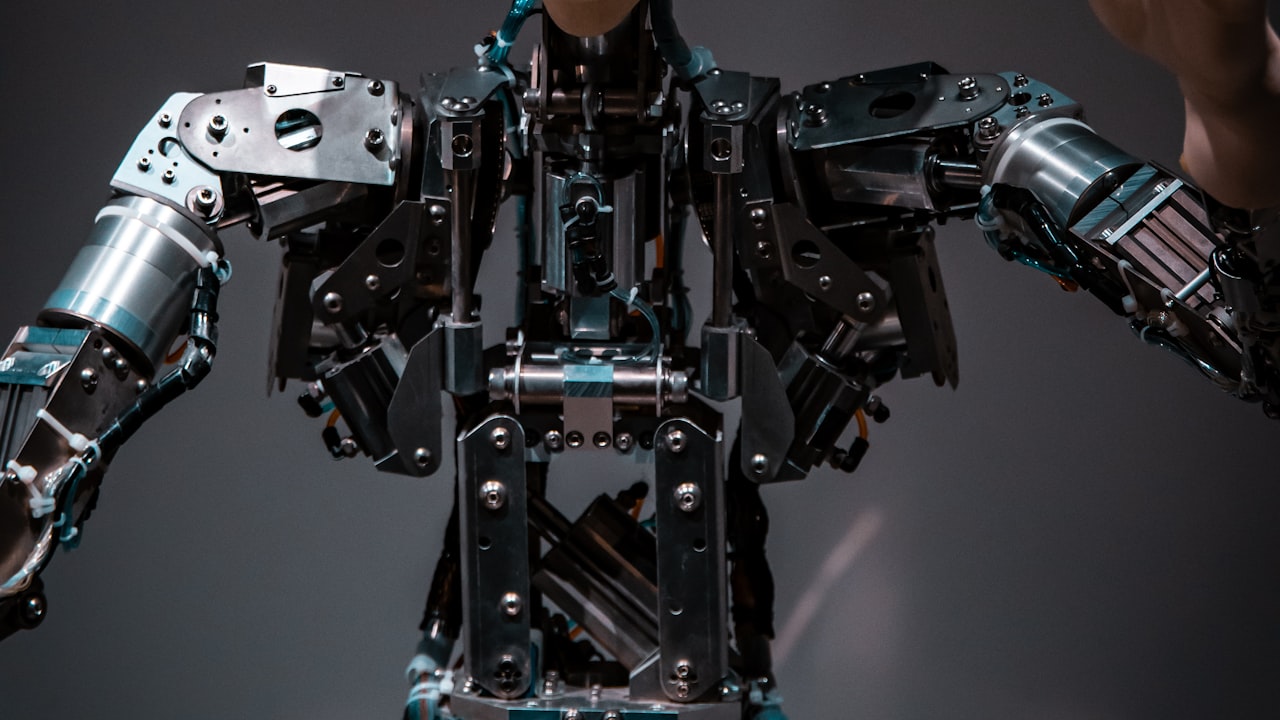

The pharmaceutical industry has been constantly evolving, driven by advancements in technology and innovation. One significant aspect of this evolution is the role of pharmaceutical machinery in streamlining production processes and ensuring the quality and efficiency of pharmaceutical products. In this article, we will explore the transformative impact of key equipment such as table press machines, capsule filling machines, and the transition from TDP to THDP technology in pharmaceutical manufacturing.

Table press machines play a crucial role in the pharmaceutical production process by compacting powdered ingredients into tablet form. These machines provide precision and consistency in tablet manufacturing, ensuring uniformity in drug dosage. With the advancement of automation and digital controls, modern table press machines have enhanced capabilities in terms of speed, accuracy, and customization options. This technology enables pharmaceutical companies to meet the growing demand for different tablet formulations while maintaining high standards of product quality.

Similarly, capsule filling machines have revolutionized the encapsulation process in pharmaceutical manufacturing. These machines automate the process of filling empty gelatin or vegetarian capsules with pharmaceutical formulations. By precisely controlling the filling process, capsule filling machines ensure accurate dosage and improve production efficiency. Pharmaceutical companies benefit from the flexibility offered by these machines, allowing them to produce a wide range of capsule formulations with varying dosages and properties to meet the diverse needs of patients.

The transition from TDP (Tablet Compression Machine) to THDP (Tablet and Capsule Hybrid Press) technology represents a significant leap in pharmaceutical machinery innovation. THDP machines combine the functionalities of traditional tablet press and capsule filling machines, offering a versatile solution for pharmaceutical manufacturers. With the ability to produce both tablets and capsules on the same machine, pharmaceutical companies can optimize production processes, reduce equipment costs, and improve overall efficiency. The integration of advanced features such as digital monitoring, remote access, and data analytics in THDP machines further enhances operational control and product quality assurance.

In conclusion, pharmaceutical machinery, including table press machines, capsule filling machines, and the latest THDP technology, plays a pivotal role in revolutionizing pharmaceutical production. These advanced equipment not only streamline manufacturing processes but also ensure the quality, consistency, and efficiency of pharmaceutical products. As the industry continues to develop, pharmaceutical companies must embrace technological advancements in machinery to stay competitive, meet regulatory standards, and ultimately deliver safe and effective medications to consumers.