Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Pharmaceutical manufacturing has evolved significantly over the years, with the introduction of advanced machines enhancing the efficiency and accuracy of the production process. Among these technological innovations, the table press machine and capsule filling machine have played a crucial role in revolutionizing pharmaceutical production.

The table press machine, commonly known as TDP (Tablet Press), is a fundamental piece of equipment in the pharmaceutical industry. It is used to compress powdered ingredients into tablets of precise sizes and shapes. With the ability to control the compression force and speed, TDP machines ensure uniformity in tablet weight and thickness, essential for maintaining dosage consistency. The automation capabilities of modern table press machines have significantly increased production rates while reducing the risk of human error.

In addition to table press machines, capsule filling machines are another indispensable tool in pharmaceutical manufacturing. These machines, such as THDP (Two-Head Double Press) models, fill empty capsule shells with powdered or liquid medication to create dosage forms suitable for oral administration. The precise dosing mechanisms of capsule filling machines ensure accurate filling levels, minimizing variations in dosage strength between individual capsules. Furthermore, the high-speed operation of modern capsule filling machines enables pharmaceutical companies to meet the growing demand for their products without compromising quality.

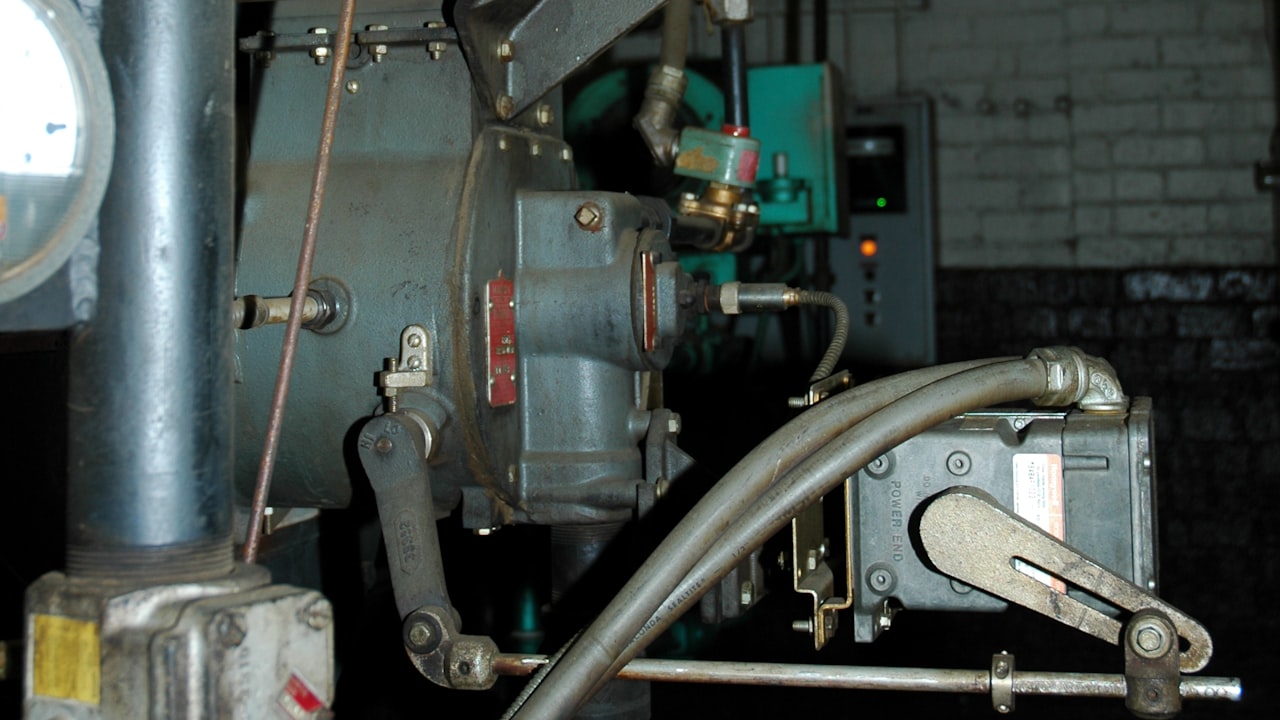

The integration of advanced technologies, such as automation, data analytics, and quality control systems, into pharmaceutical machinery has further optimized the production process. Automated features, such as self-cleaning mechanisms and real-time monitoring of production parameters, enhance operational efficiency and minimize downtime for maintenance. Data analytics tools provide valuable insights into manufacturing processes, enabling pharmaceutical companies to identify and address potential issues proactively. Quality control systems ensure compliance with regulatory standards and product specifications, safeguarding the integrity and safety of pharmaceutical products.

In conclusion, the advancements in pharmaceutical machinery, including table press machines and capsule filling machines, have transformed the production landscape of the pharmaceutical industry. These innovative technologies have not only increased efficiency and productivity but also improved the quality and consistency of pharmaceutical products. As the demand for precision medicine continues to rise, pharmaceutical manufacturers will rely on cutting-edge machinery to meet the evolving needs of patients worldwide.