Article Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutic Machines”

Article Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutic Machines”

Pharmaceutical manufacturing has significantly advanced with the utilization of cutting-edge pharmaceutic machines such as table press machines, capsule filling machines, TDP, and THDP. These machines play a crucial role in streamlining the production process, ensuring efficiency, accuracy, and consistency in drug manufacturing.

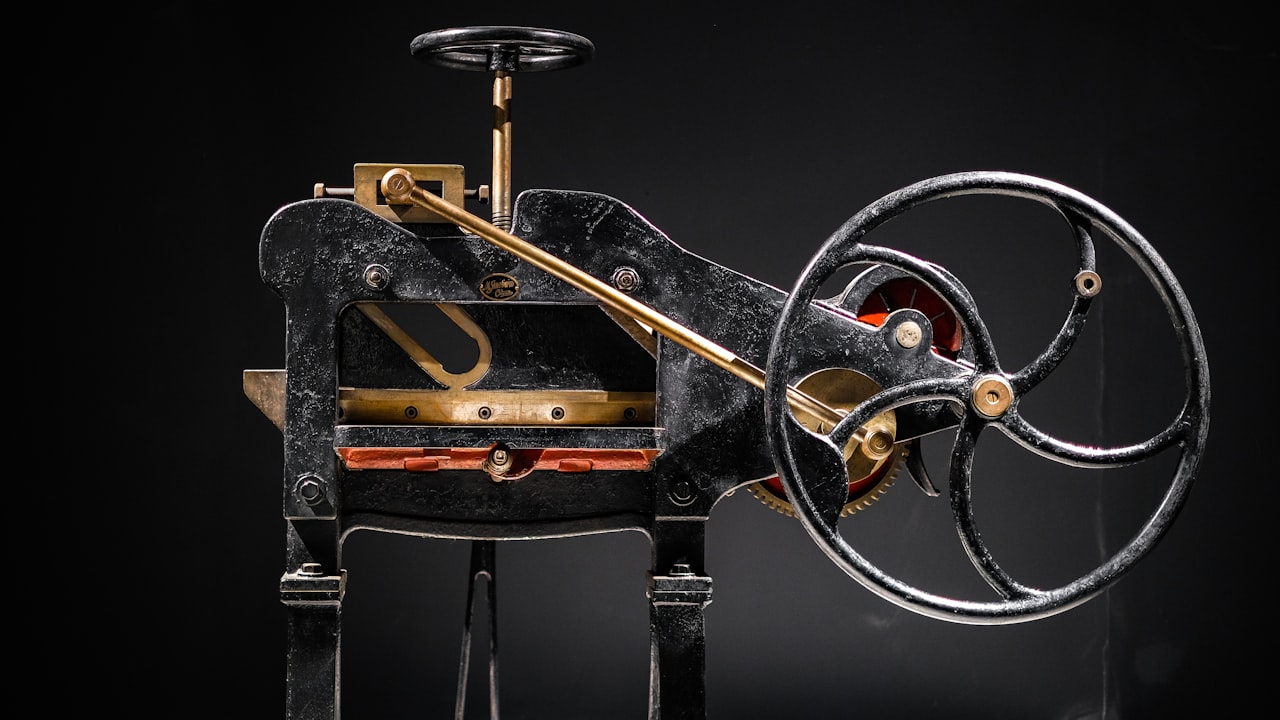

Table press machines are indispensable in the pharmaceutical industry as they are used to compress powdered ingredients into tablets of specific shapes and sizes. These machines operate by exerting high pressure on the powder within the die cavity, resulting in the formation of tablets that meet the required standards. By automating the tablet compression process, table press machines enhance productivity and reduce the likelihood of human error, thus improving the overall quality of pharmaceutical products.

In contrast, capsule filling machines are designed to encapsulate powdered or granulated ingredients into gelatin or vegetarian capsules. These machines offer precise control over the filling process, ensuring that each capsule contains the exact dosage of the active pharmaceutical ingredient. With the ability to fill hundreds or even thousands of capsules per minute, capsule filling machines have revolutionized the production of pharmaceutical formulations, enabling manufacturers to meet demand efficiently and effectively.

TDP (Tablet Press) and THDP (Tablet Hardness Tester) are essential components of pharmaceutical manufacturing processes. TDP machines are specifically designed to produce tablets in large quantities, offering high-speed production capabilities and consistent tablet quality. On the other hand, THDP machines are used to measure the hardness of tablets, ensuring that they meet the required standards for dissolution and absorption in the body. By integrating TDP and THDP machines into the manufacturing process, pharmaceutical companies can enhance product quality and compliance with regulatory standards.

In conclusion, pharmaceutic machines such as table press machines, capsule filling machines, TDP, and THDP play a pivotal role in revolutionizing pharmaceutical manufacturing. By incorporating advanced technologies and automation into the production process, these machines improve efficiency, accuracy, and consistency, ultimately leading to the development of high-quality pharmaceutical products that meet the needs of patients worldwide.