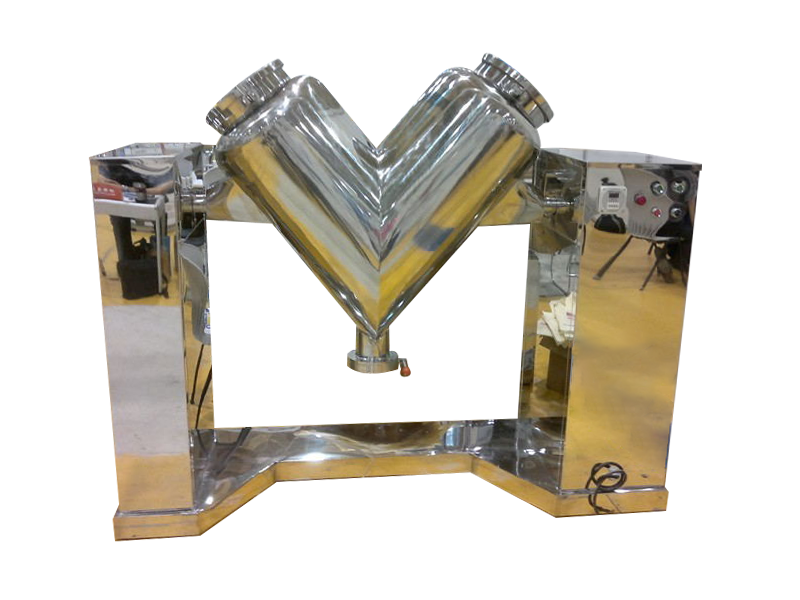

Description

V Type powder Blender information

1.Compact structure, simple operation, stable operation, no noise;

2. It can adapt to the mixing of various materials, and the uniformity rate is 98%;

3. When mixing materials with frictional properties, the V-type mixer has a good mixing effect;

4. When mixing materials with good fluidity and similar physical properties, a better mixing effect can be obtained;

| Model | V-100 | V-200 | V-500 |

| Production capacity(kg) | 40 | 80 | 200 |

| Mixing time(min) | 4-8 | 6-10 | 6-10 |

| Full volume | 100 | 200 | 500 |

| Stirring speed(r/min) | 12 | 12 | 12 |

| Power(kw) | 0.75 | 1.1 | 2.2 |

| Machine size(mm) | 1600*650*1300 | 1700*650*1500 | 2500*1220*2420 |

| Machine weight(kg) | 280 | 320 | 550 |

| Model | V-1000 | V-1500 | V-2500 |

| Production capacity(kg) | 400 | 600 | 1000 |

| Mixing time(min) | 6-10 | 6-10 | 6-10 |

| Full volume | 1000 | 1500 | 2500 |

| Stirring speed(r/min) | 12 | 12 | 12 |

| Power(kw) | 4 | 4 | 7.5 |

| Machine size(mm) | 2975*1660*3000 | 3190*1990*3790 | 3900*1990*3790 |

| Machine weight(kg) | 950 | 2000 | 2000 |

V Type powder Blender is composed of two cylinders welded together in a V shape, and the shape of the container is asymmetric with respect to the axis. Due to the rotating movement, the powder and granular bodies are continuously alternated, divided and merged in the inclined cylinder. The material is randomly transferred from one area to another, and at the same time, there is a slippage between the powder and granular particles, and the space is superimposed multiple times. V Type powder Blender are continuously distributed on the newly generated surface, so that the shearing and diffusion movement are repeated to achieve mixing.

Reviews

There are no reviews yet.