Description

| Model | RE-10 | RE-20 | RE-30 | RE-50 |

| Spin bottle capacity(L) | 10 | 20 | 30 | 50 |

| Spin bottle | Flange ø95/125 | Flange ø125 | Flange ø125 | Flange ø125 |

| Collection bottle(L) | 5 | 10 | 20 | 20 |

| Host speed(r/min) | 10-120 | 10-120 | 10-90 | 10-90 |

| Condensing area(m²) | 0.57 | 1 | 1.3 | 1.5 |

| Evaporation rate | H₂O>3L/h | H₂O>5L/h | H₂O>7L/h | H₂O>9L/h |

| Bath pot power(kw) | 3 | 3 | 3 | 3 |

| Use ambient temperature(℃) | 5-35 | 5-35 | 5-35 | 5-35 |

| Ambient relative humidity | ≤65% | ≤65% | ≤65% | ≤65% |

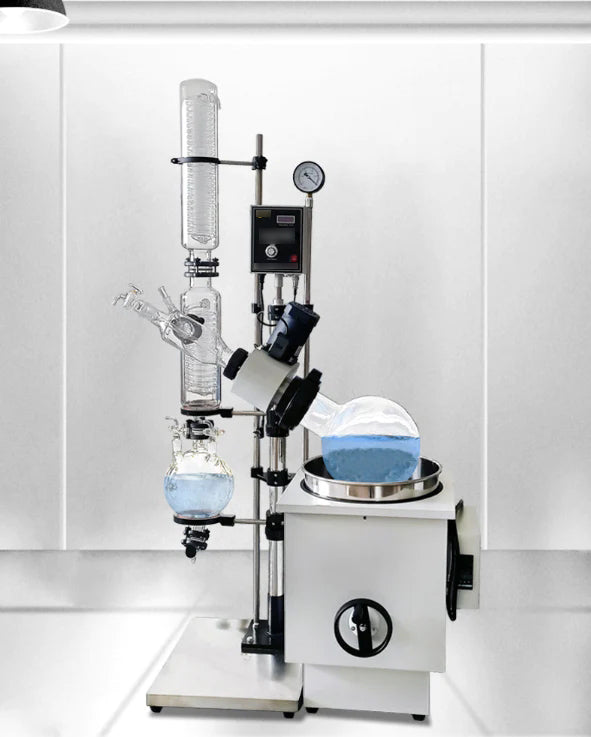

Rotary(Vacuum) Evaporator

Principle: different boiling points/rotation at a suitable speed and constant speed to increase the evaporation area;

Application: Continuous distillation of volatile solvents under reduced pressure.

Application areas: solvent extraction or separation in chemistry, chemical industry, biomedicine and other fields

mixture;

Application cases: 1. Solvent recovery: commonly used to recover washing solvents, such as ethanol,

Acetone, carbon tetrachloride, etc.

2. Vacuum drying of wet solids: commonly used in the pharmaceutical and food industries to remove moisture or organic solvents from wet powders such as syrups, sugars, jams and dehydrated vegetables.

3. Solution concentration: concentrated electroplating waste liquid (gold, silver, copper, nickel, etc.); emulsified cutting fluid waste water; sludge concentration and dehydration;

Grinding waste liquid; paint waste liquid; hydrofluoric acid treatment waste water; ammonium sulfate waste liquid and other kinds of salt waste liquid.

4. Extraction of essential oils: Put plants (such as roots, stems or leaves) into a rotary bottle, add 5~10 times of solvents such as water, ethanol, methanol, acetone (according to specific technical requirements), under normal pressure/negative pressure Heating at a constant temperature while distilling while rotating, and repeating multiple times through condensation and reflux to obtain the target solvent.

Reviews

There are no reviews yet.