Description

PRODUCT APPLICATION

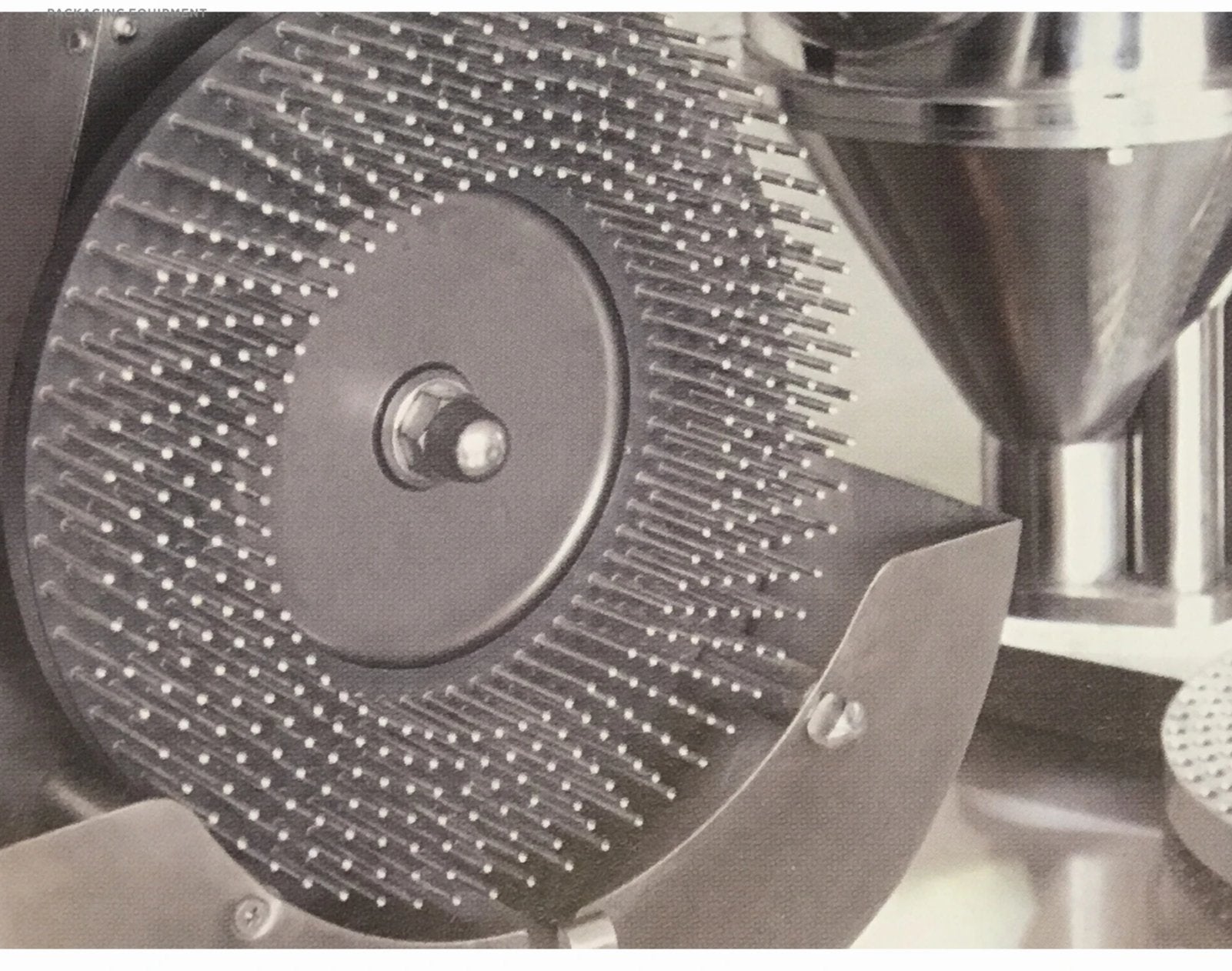

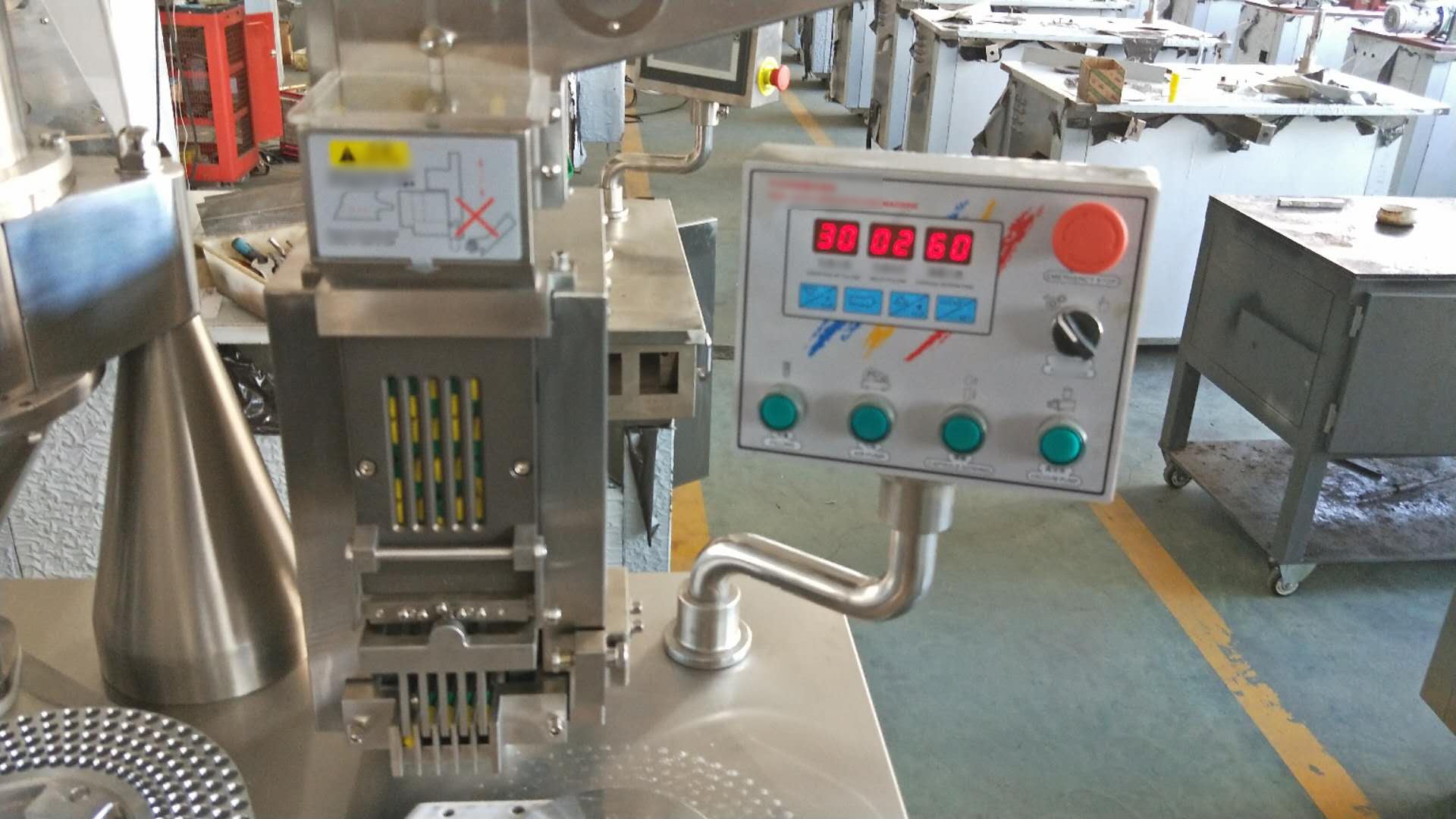

CGN208-D type capsul filling machine is a new efficient equipment based on DTJ-C model (old type) after research and development: easier more intuitive and higher loading in capsule dropping,U-turning, vacuum separation in comparison with the old type.The new type of capsule orientating adopts columns pill positioning design,which shortens the time in the replacement of mould from original 30 minutes to 5-8 minutes.

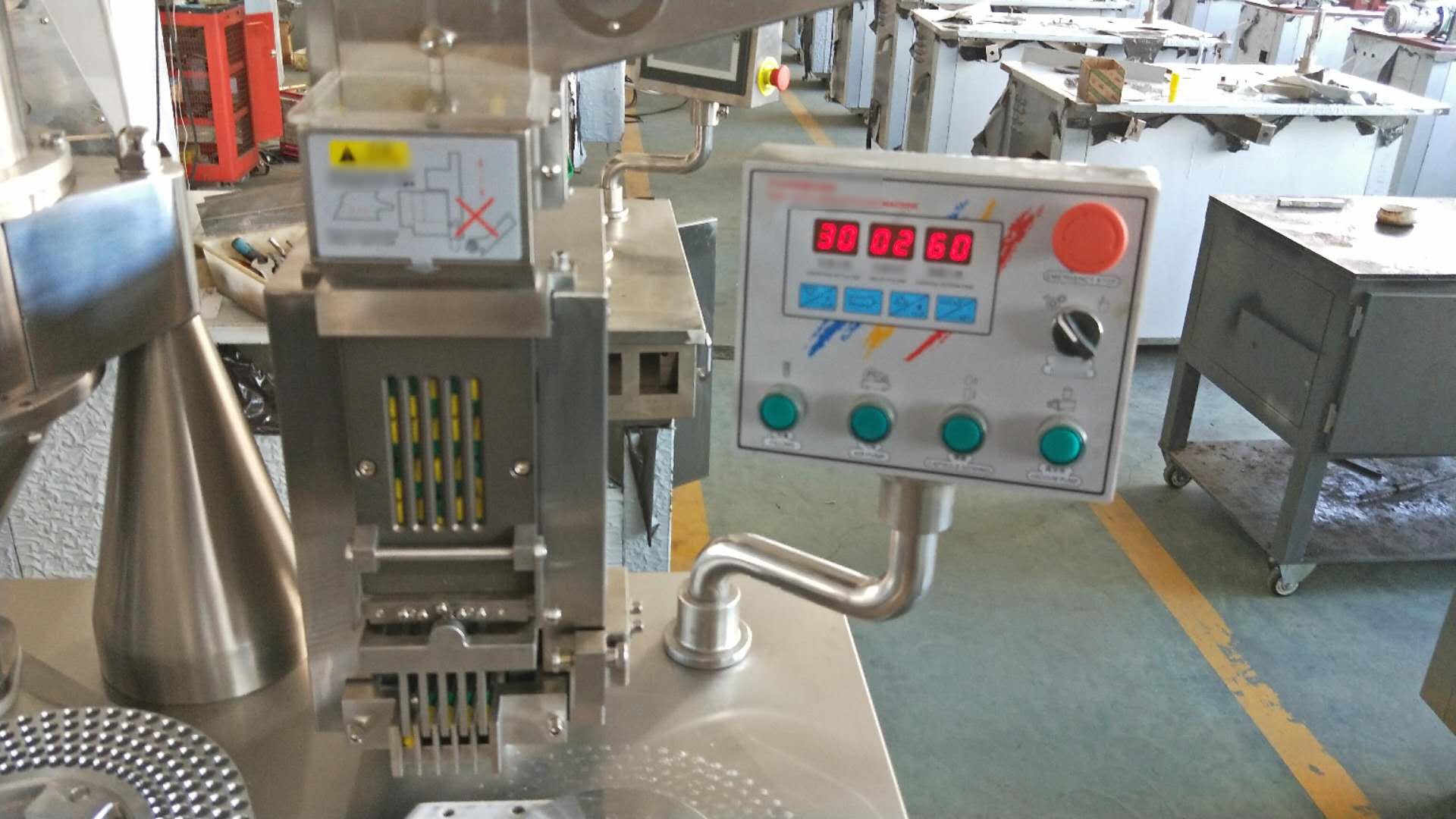

This machine is one type of electricity and pneumatic combined control,automatic counting electronics,programmable controller and frequency conversion speed regulating device.Instead of manual filling,it reduces labor intensity,which is the ideal equipment for capsule filling for small and medium-sized pharmaceutical companies,pharmaceutical research and development institutions and hospital preparation room.

|

MAIN SPECIFICATIONS

|

||||

|

Model

|

CGN208-D

|

|||

|

Mould Debugging Time

|

5-8 minutes

|

|||

|

Productivity

|

10000-30000 Capsutes/hour

|

|||

|

Capsule size

|

000#,00L#,00#,0L#,0#,1#,2#,3#,4#

|

|||

|

Power

|

220V/380V 50Hz 3PH 4.0kw

|

|||

|

Dimensions

|

1750 x 870 x 1750 mm

|

|||

|

Weight

|

540kg

|

|||

MAIN FEATURES

1) Machine is used for the sealing of capsul cap and capsul body in 00#~4# size.

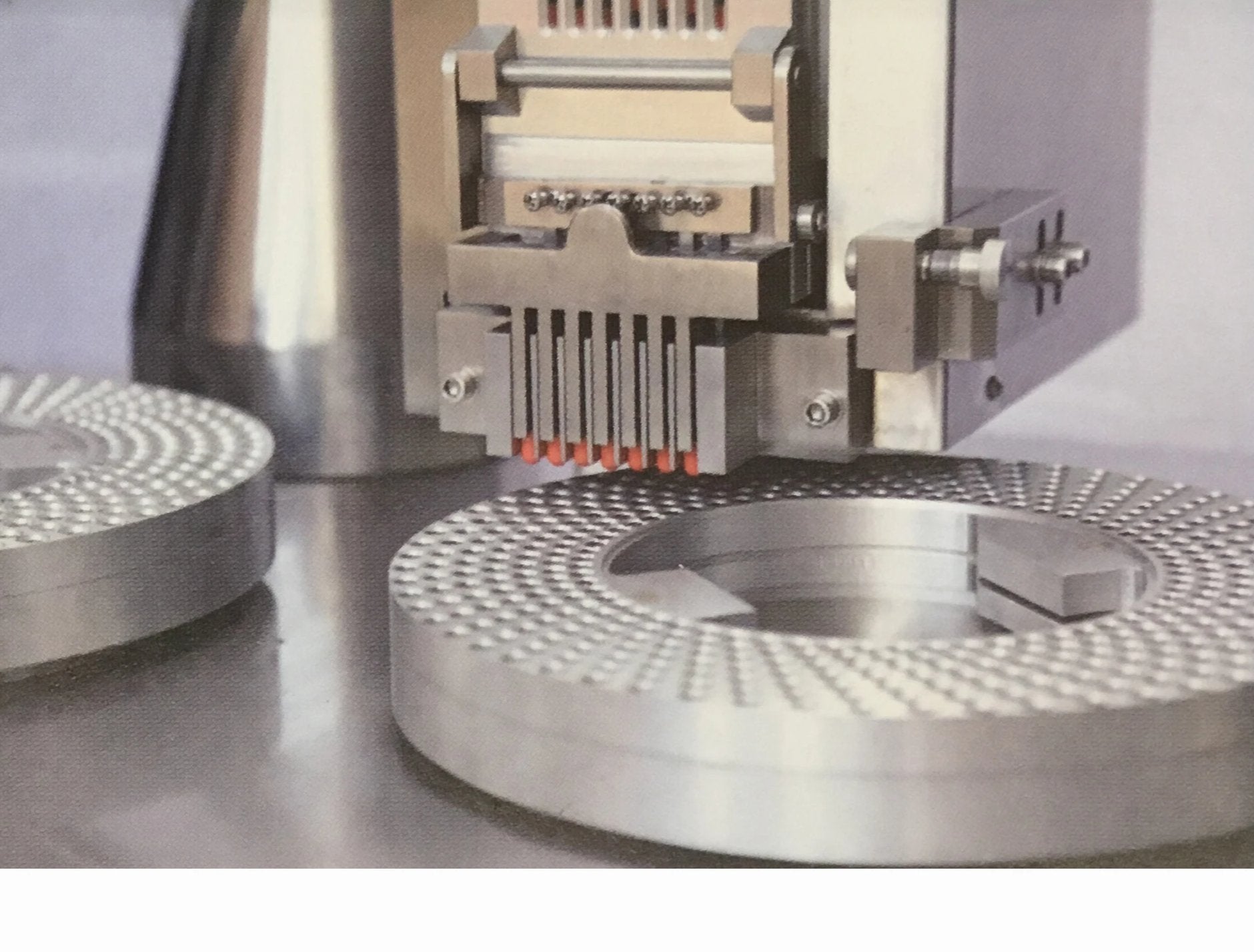

2) Equipped with electronic automatic counting device, speed control device, respectively to do the capsule in place, separation, filling, locking and other actions, instead of manual filling to improve production efficiency.

3) Simple operation, easy maintenance, low power consumption, high production efficiency.

4) Key parts, hopper, table with stainless steel, the overall stainless steel body, meet GMP production specifications.

5) Easy to operate, easy to change the mould.

Reviews

There are no reviews yet.