Title: Pharmaceutical Machinery: Revolutionizing the Medicine Production Industry

Title: Pharmaceutical Machinery: Revolutionizing the Medicine Production Industry

Pharmaceutical machinery plays a crucial role in the production of medicines, ensuring efficiency, accuracy, and quality in the pharmaceutical industry. Among the various types of pharmaceutical machinery, the table press machine and capsule filling machine stand out as essential tools in the medicine manufacturing process.

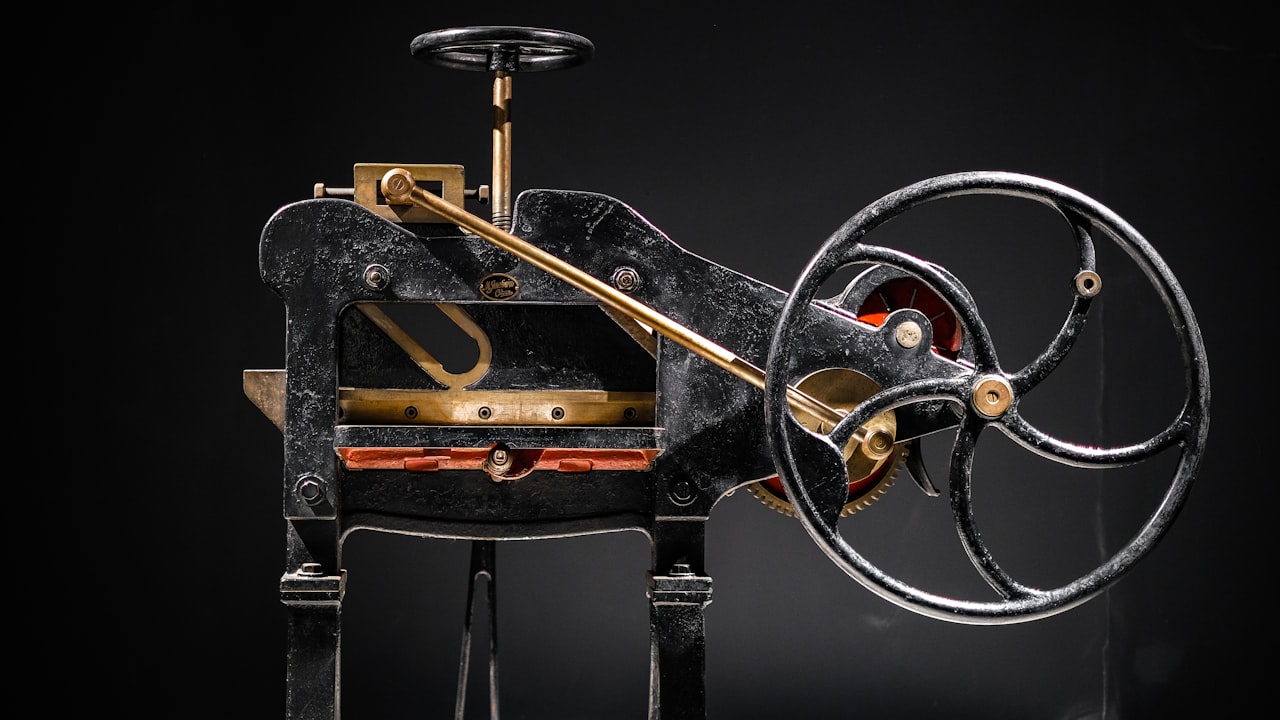

Tablet press machines are commonly used in pharmaceutical manufacturing to compress powder or granules into tablets of uniform size and weight. These machines come in different types, with the TDP (Tablet Press) and THDP (Tablet Hardness Tester) being popular choices. The TDP is known for its reliability and precision in tablet production, allowing pharmaceutical companies to mass-produce tablets with consistent quality. On the other hand, the THDP is crucial for ensuring the hardness and durability of tablets, which is essential for their stability and effectiveness.

Capsule filling machines are another vital component of pharmaceutical machinery, used to fill empty hard gelatin or vegetable capsules with powdered or granular materials. These machines automate the process of filling and sealing capsules, increasing efficiency and reducing human error. By utilizing capsule filling machines, pharmaceutical companies can produce a large volume of capsules quickly and accurately, meeting the demands of the market.

Overall, the advancement of pharmaceutical machinery, including table press machines and capsule filling machines, has revolutionized the medicine production industry. These machines have enabled pharmaceutical companies to increase production capacity, improve product quality, and meet regulatory standards more effectively. As technology continues to advance, we can expect further innovations in pharmaceutical machinery, leading to even greater efficiency and precision in medicine manufacturing.