Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

In the dynamic world of pharmaceutical manufacturing, the use of advanced machinery has become indispensable for enhancing efficiency, precision, and productivity. Two key pieces of equipment that have revolutionized the industry are the table press machine and the capsule filling machine. These machines play a crucial role in the production process, particularly in the manufacture of solid dosage forms such as tablets and capsules.

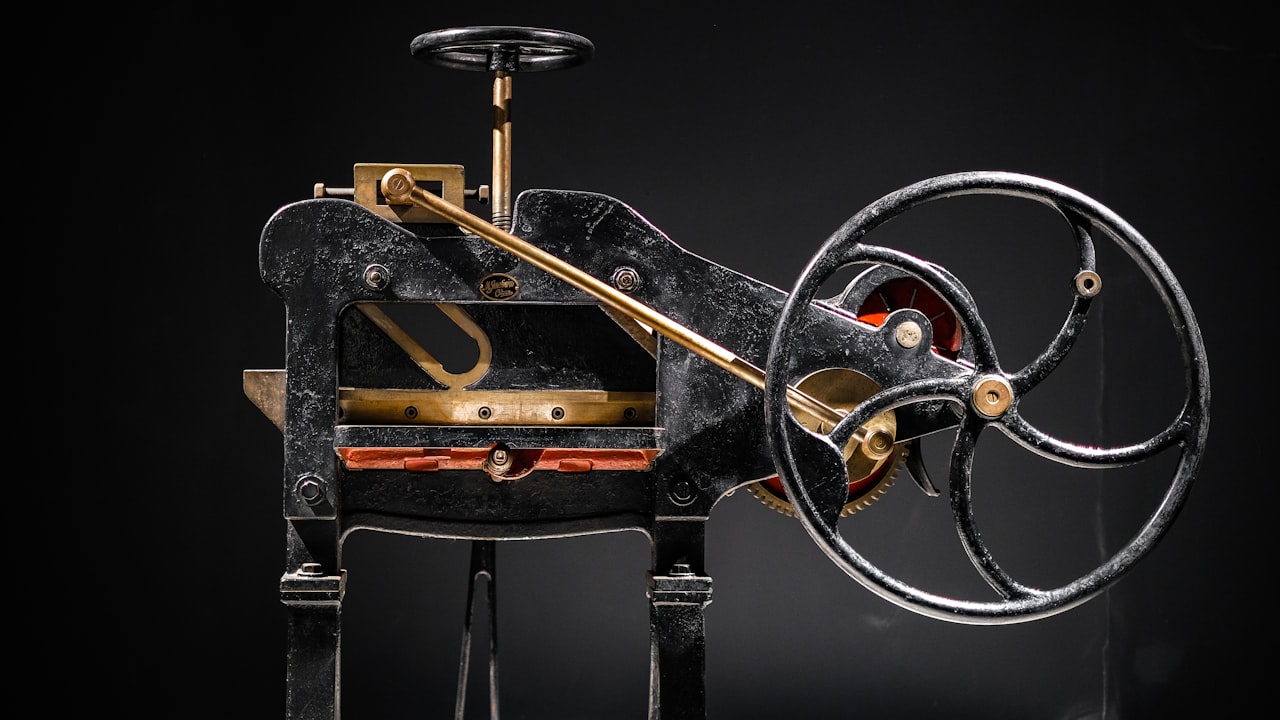

The table press machine, also known as a tablet press, is a fundamental tool in pharmaceutical production. It is used to compress powdered ingredients into tablets of precise size, shape, and weight. The process begins with the preparation of the tablet formulation, which typically consists of active pharmaceutical ingredients, excipients, and binding agents. The tablet press then compresses the formulation into tablets using a combination of compression force and die specifications. The emergence of advanced table press machines, such as the TDP (Tablet Deduster Press) and THDP (Tablet Hardness Testing Press), has further optimized the tablet production process. These machines offer features like automatic dedusting and hardness testing, ensuring the quality and consistency of the final product.

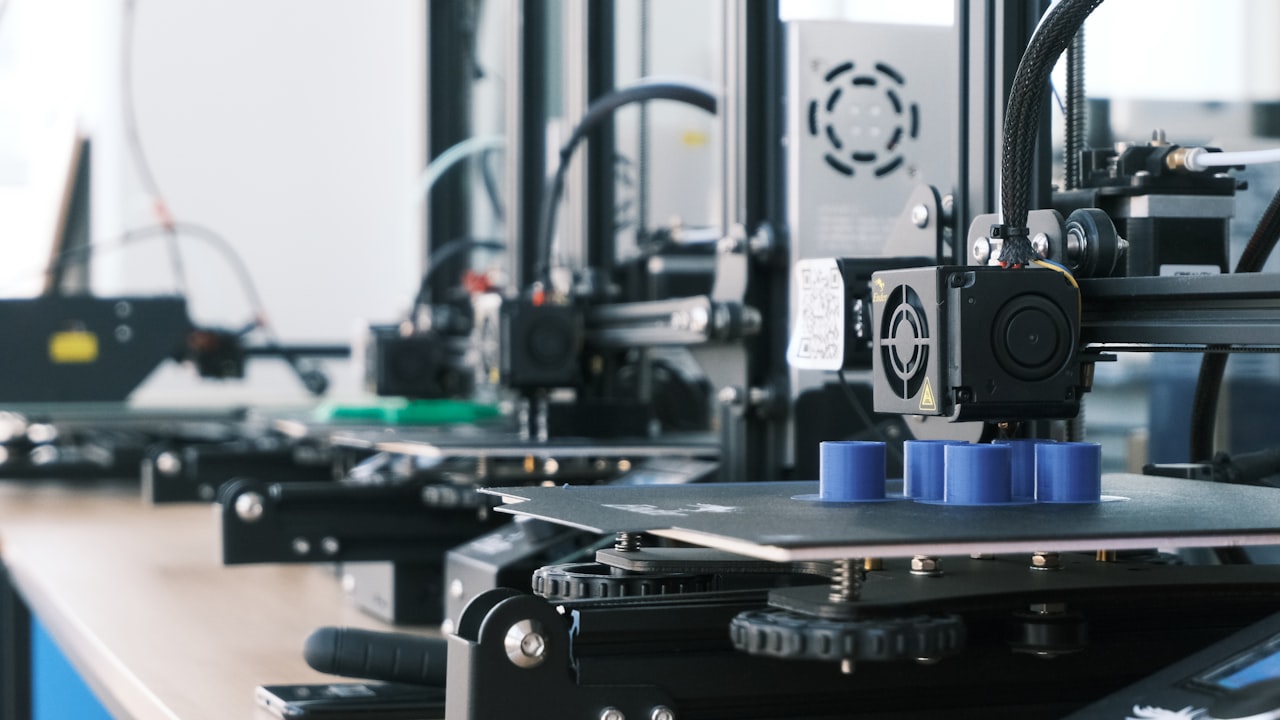

On the other hand, capsule filling machines are essential for the efficient encapsulation of powdered or granulated materials. These machines come in various types, including automatic capsule fillers and semi-automatic capsule fillers, depending on the production scale and required output. The capsule filling process involves filling empty gelatin or vegetarian capsules with the desired formulation, followed by cap sealing to secure the contents. Modern capsule filling machines are equipped with advanced technologies to control dosage accuracy, minimize wastage, and increase production speed. The development of high-speed capsule filling machines has significantly boosted production capacities in pharmaceutical manufacturing facilities.

Overall, the integration of table press machines and capsule filling machines has transformed pharmaceutical production by streamlining processes, ensuring product quality, and meeting the growing demand for pharmaceutical products. These machines have not only increased production efficiency but have also contributed to the development of innovative dosage forms and drug delivery systems. As technology continues to advance, the pharmaceutical industry will witness further enhancements in machinery automation, data integration, and process optimization, driving continuous improvements in pharmaceutical manufacturing.

In conclusion, the utilization of table press machines and capsule filling machines has played a vital role in revolutionizing pharmaceutical production. These advanced pieces of equipment have become indispensable assets for pharmaceutical manufacturers, enabling them to meet the evolving demands of the global market. By investing in cutting-edge machinery and embracing technological innovations, pharmaceutical companies can stay competitive, uphold quality standards, and deliver safe and effective medications to patients worldwide.

(Word count: 395)

Title: Pharmaceutical Machinery: Revolutionizing the Medicine Production Industry

Title: Pharmaceutical Machinery: Revolutionizing the Medicine Production Industry Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery Title: The Role of Pharmaceutical Machinery in Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Drug Manufacturing Title: “Revolutionizing Pharmaceutical Industry with Advanced Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Industry with Advanced Pharmaceutical Machinery” Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing” Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery Article Title: “Revolutionizing Pharmaceutical Production: Advanced Technologies in Pharmaceutical Machinery”

Article Title: “Revolutionizing Pharmaceutical Production: Advanced Technologies in Pharmaceutical Machinery” Title: “The Revolution of Pharmaceutical Machinery: Enhancing Efficiency and Quality in Drug Production”

Title: “The Revolution of Pharmaceutical Machinery: Enhancing Efficiency and Quality in Drug Production”