Title: “Revolutionizing Pharmaceutical Industry: The Power of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Industry: The Power of Pharmaceutical Machinery”

In the rapidly evolving landscape of the pharmaceutical industry, the utilization of cutting-edge pharmaceutical machinery has emerged as a pivotal driver of innovation, efficiency, and safety. Among the plethora of indispensable equipment within this realm, the table press machine and capsule filling machine sparkle as shining beacons of technological prowess, reshaping the way medications are produced and delivered to patients worldwide.

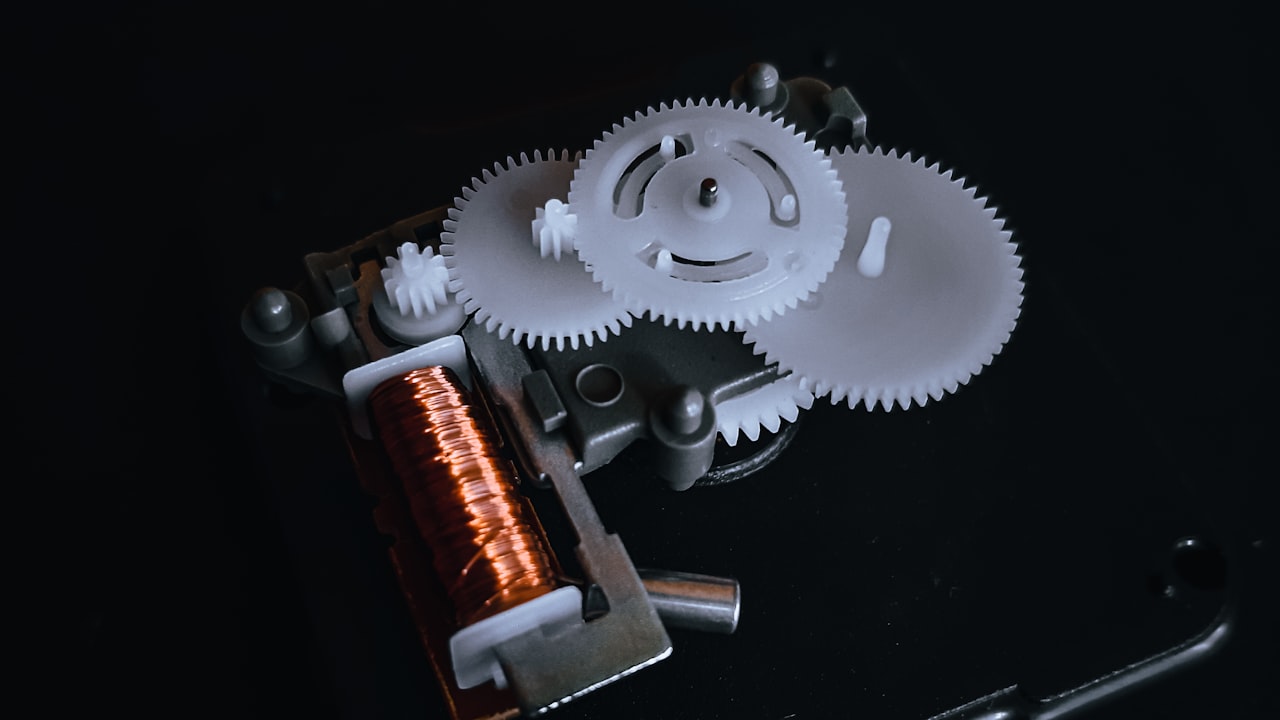

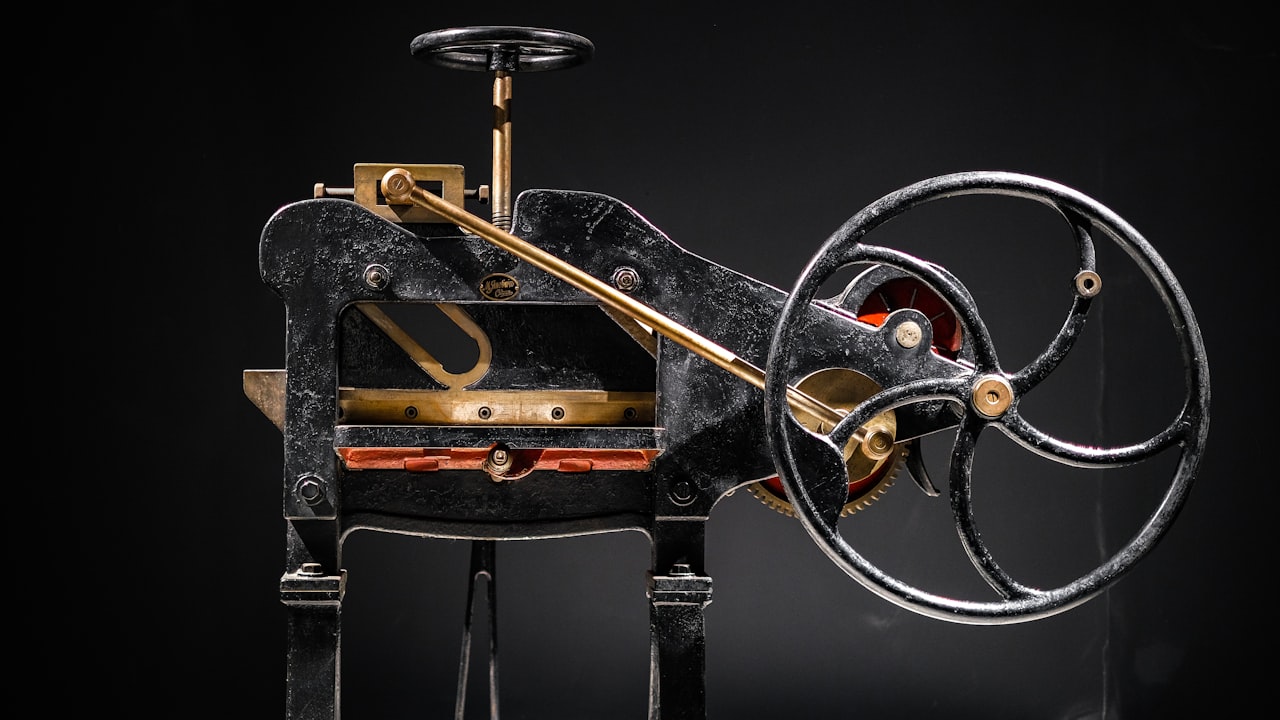

One of the quintessential components of pharmaceutical machinery is the table press machine, a versatile apparatus that is instrumental in the manufacturing of tablets. With the ability to compress powdered ingredients into precise, uniform tablets, table press machines embody the essence of efficiency and accuracy in pharmaceutical production. These machines are designed to meet the stringent requirements of pharmaceutical manufacturing standards, such as the Tablet Deduster Machine (TDP) and the Tablet Hardness Tester (THDP), ensuring that each tablet meets the highest quality standards before reaching the hands of patients.

Similarly, the capsule filling machine stands as a cornerstone of pharmaceutical manufacturing, offering a sophisticated solution for encapsulating powdered or liquid medications. By seamlessly filling and sealing capsules with meticulous precision, these machines play a vital role in ensuring dosage accuracy, drug efficacy, and patient safety. Through advanced technologies and automation, capsule filling machines streamline the encapsulation process, minimizing human error and enhancing production efficiency.

The integration of table press machines and capsule filling machines within pharmaceutical facilities revolutionizes the production of medications by optimizing manufacturing processes, enhancing product quality, and ultimately improving patient outcomes. The synergy between these state-of-the-art machines and pharmaceutical expertise enables healthcare providers to deliver life-saving medications with precision, consistency, and reliability.

In conclusion, the transformative impact of pharmaceutical machinery, particularly table press machines and capsule filling machines, cannot be overstated in the context of the pharmaceutical industry. As technological advancements continue to propel the sector forward, the enduring significance of these machineries in shaping the future of pharmaceutical manufacturing and healthcare delivery remains resolute, underscoring their pivotal role in safeguarding the well-being of patients worldwide.

Title: Revolutionizing the Pharmaceutical Industry: The Impact of Modern Drug Manufacturing Technologies

Title: Revolutionizing the Pharmaceutical Industry: The Impact of Modern Drug Manufacturing Technologies Title: The Role of Pharmaceutical Machinery in Drug Production

Title: The Role of Pharmaceutical Machinery in Drug Production Title: The Role of Pharmaceutical Machinery in Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Drug Manufacturing Title: The Evolution of Pharmaceutical Machinery: Enhancing Drug Manufacturing Efficiency

Title: The Evolution of Pharmaceutical Machinery: Enhancing Drug Manufacturing Efficiency Title: Revolutionizing Pharmaceutical Production: The Impact of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Impact of Pharmaceutical Machinery Title: “Revolutionizing Pharmaceutical Manufacturing through Advanced Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing through Advanced Pharmaceutical Machinery” “Revolutionizing Pharmaceutical Manufacturing with Advanced Pharmaceutical Machinery”

“Revolutionizing Pharmaceutical Manufacturing with Advanced Pharmaceutical Machinery” Title: The Role of Pharmaceutical Machinery in the Modern Medicine Industry

Title: The Role of Pharmaceutical Machinery in the Modern Medicine Industry Title: Revolutionizing Pharmaceutical Production: The Impact of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Production: The Impact of Pharmaceutical Machinery