Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

In the realm of modern drug manufacturing, the utilization of advanced pharmaceutical machinery plays a pivotal role in ensuring the efficiency, precision, and safety of the production process. Two key players in this arena are the table press machine and the capsule filling machine. This article explores the functions and significance of these machines in pharmaceutical manufacturing, focusing on the TDP (Tablet Press) and THDP (Tablet Hardness Testing) machines.

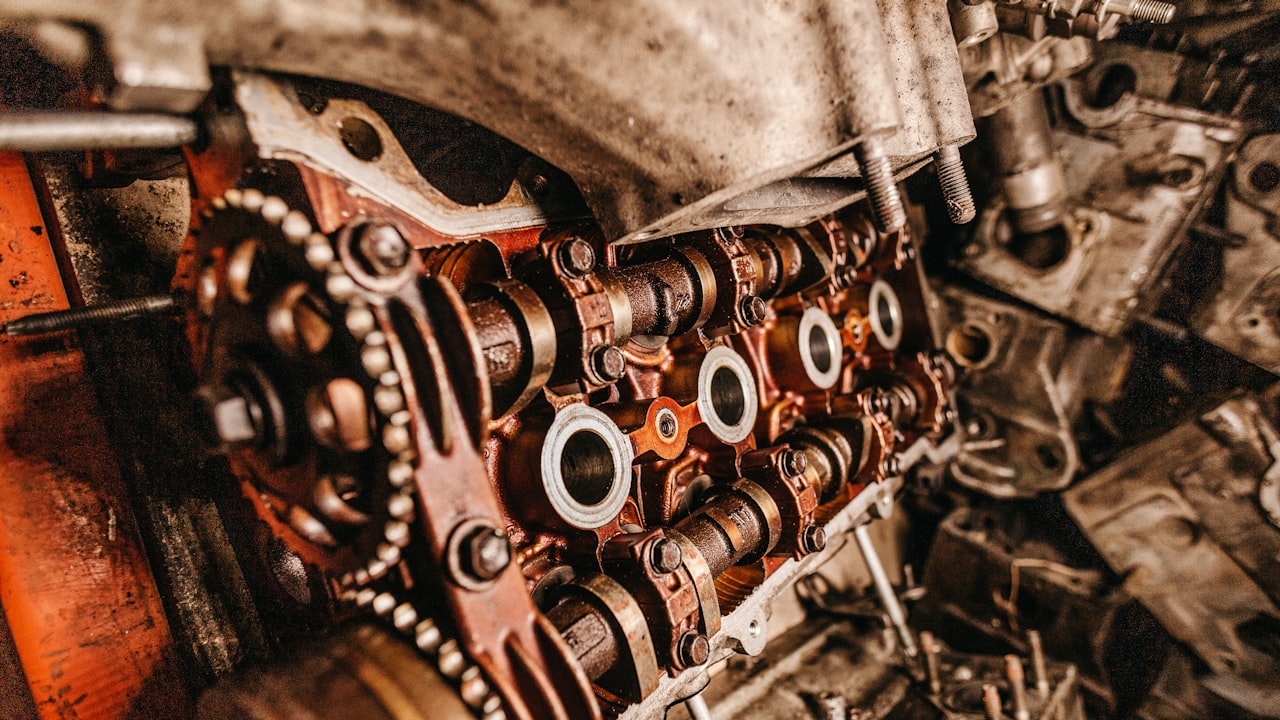

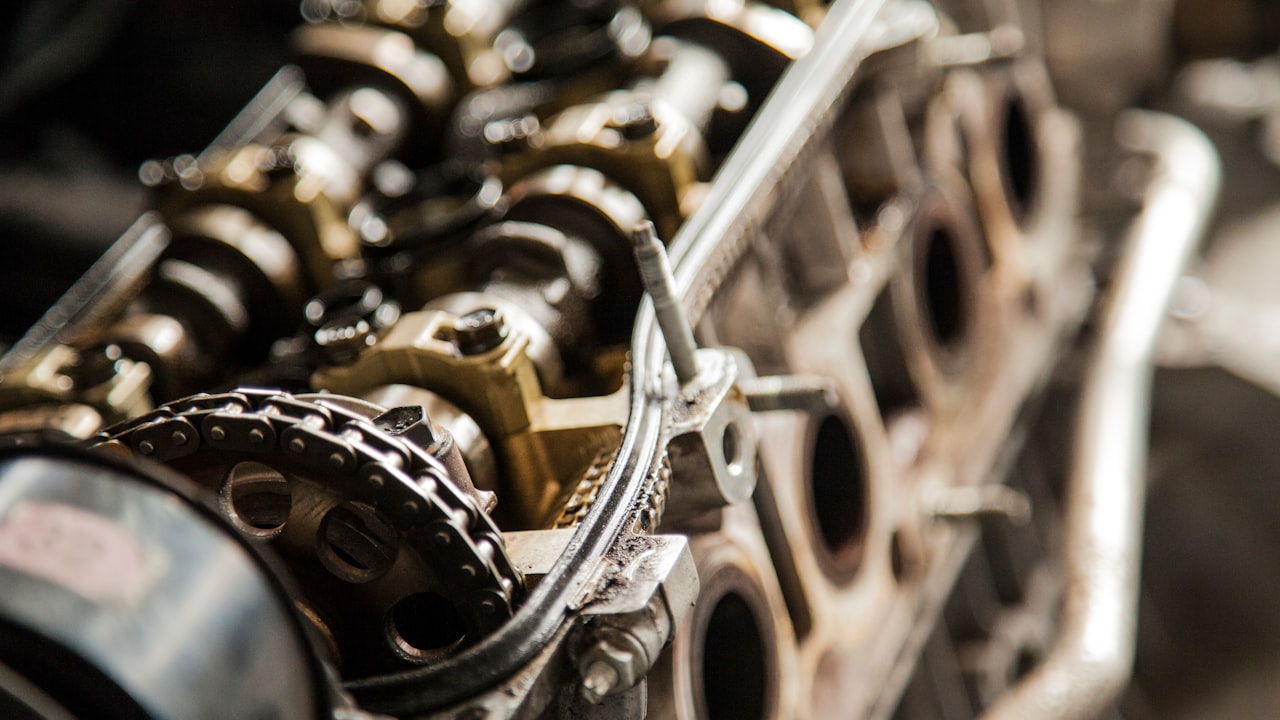

The table press machine, commonly known as a tablet press, is an essential piece of equipment in drug manufacturing facilities. Its primary function is to compress powdered materials into tablets of precise sizes and weights. By exerting controlled pressure on the powder, the machine forms tablets that meet pharmaceutical standards. The table press machine operates through a series of intricate mechanisms that ensure uniformity and consistency in tablet production.

On the other hand, the capsule filling machine is designed to streamline the process of filling capsules with powdered or granulated substances. This machine automates the task of filling, sealing, and ejecting capsules, reducing the risk of human error and contamination. The capsule filling machine is equipped with mechanisms that accurately dispense the appropriate amount of material into each capsule, ensuring dosage uniformity and quality.

The TDP (Tablet Press) machine is a specific type of table press machine widely used in the pharmaceutical industry. It is prized for its efficiency, ease of use, and versatility in producing various types of tablets. The TDP machine can be customized to meet different manufacturing requirements, such as adjusting the tablet size, shape, and hardness. Its precision engineering and reliable performance make it a popular choice for pharmaceutical companies seeking high-quality tablet production.

Conversely, the THDP (Tablet Hardness Testing) machine plays a critical role in quality control within drug manufacturing processes. This machine measures the hardness of tablets to ensure they meet the desired specifications. By conducting hardness tests, pharmaceutical manufacturers can assess the structural integrity and dissolution properties of tablets, guaranteeing their efficacy and safety for consumers.

In conclusion, pharmaceutical machinery, including table press and capsule filling machines like the TDP and THDP, are indispensable tools in modern drug manufacturing. These machines enable pharmaceutical companies to produce tablets and capsules with precision, consistency, and quality. By incorporating advanced machinery into their production facilities, pharmaceutical manufacturers can enhance efficiency, reduce costs, and uphold stringent quality standards in the development of life-saving medications.

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machines

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machines Title: **The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes**

Title: **The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes** Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes” Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery Title: **Revolutionizing Medicine: The Role of Pharmaceutical Machinery in Drug Production**

Title: **Revolutionizing Medicine: The Role of Pharmaceutical Machinery in Drug Production** Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery” Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing” Title: “The Evolution of Pharmaceutical Machinery: Innovations in Drug Manufacturing”

Title: “The Evolution of Pharmaceutical Machinery: Innovations in Drug Manufacturing” Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharma Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharma Machinery”