Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”

In the constantly evolving landscape of the pharmaceutical industry, the role of pharmaceutical machinery cannot be underestimated. Among the various types of machinery used in pharmaceutical manufacturing, table press machines and capsule filling machines play a crucial role in ensuring the efficiency and quality of the final medicinal products.

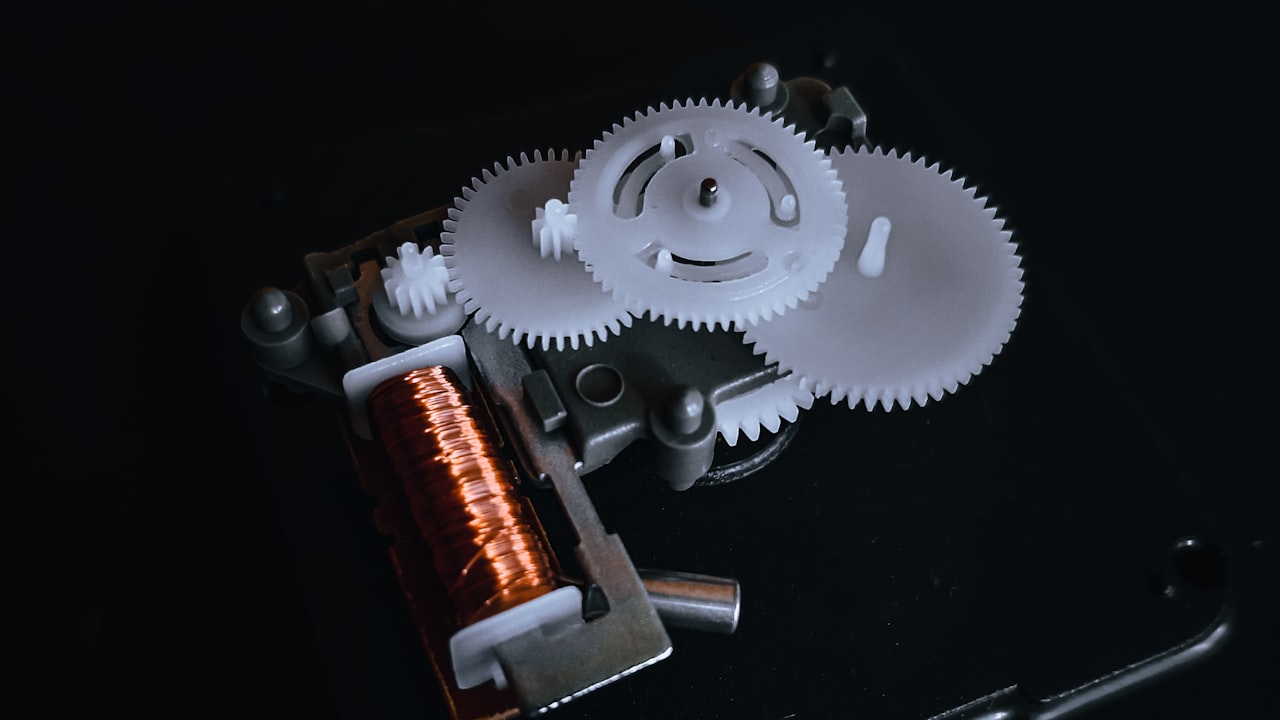

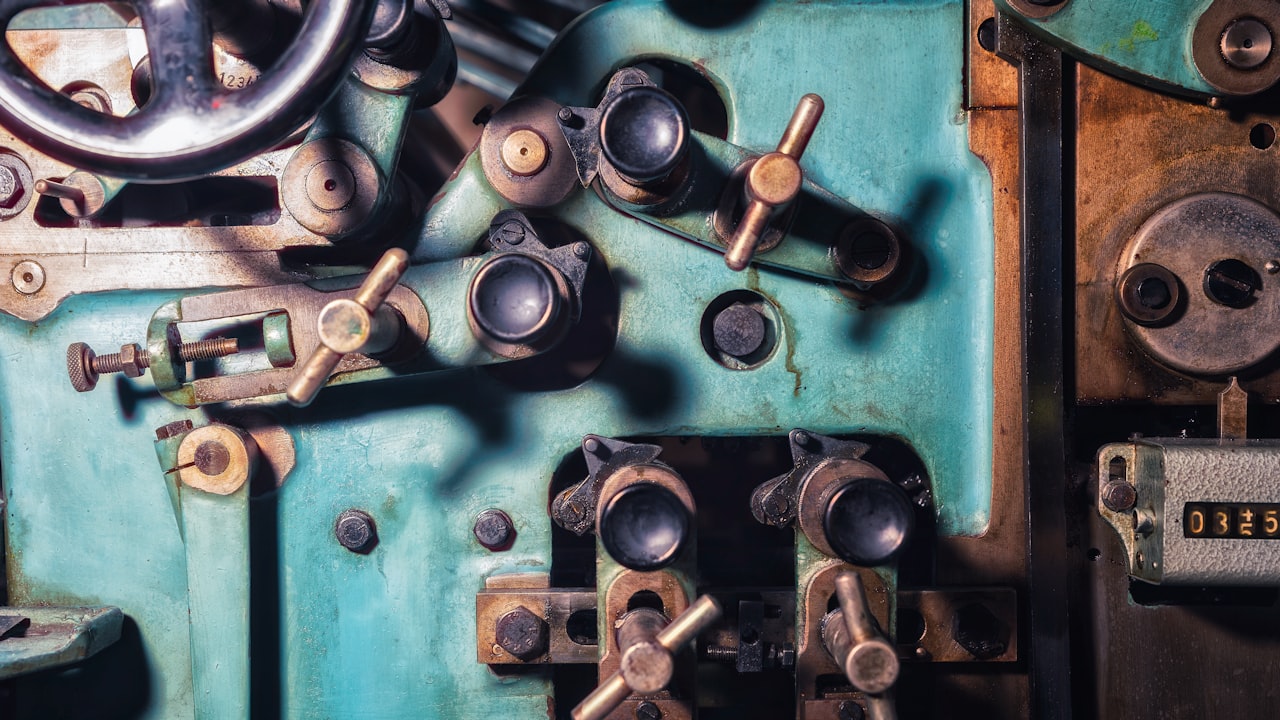

Tablet press machines, commonly referred to as tableting machines, are essential in the production of tablets or pills. These machines operate by compressing powdered ingredients into a solid dose form. One popular type of table press machine is the TDP (Tablet Press). This machine uses mechanical force to compact the powdered materials into tablets of uniform shape and size. The efficiency and precision of the TDP machine contribute significantly to the speed and consistency of tablet production in pharmaceutical manufacturing settings.

On the other hand, capsule filling machines are instrumental in the encapsulation process. These machines are designed to fill empty capsule shells with powdered or granulated ingredients. The THDP (Tablet in Capsule Filling Machine) is a notable example of advanced capsule filling equipment that streamlines the process of combining tablets and capsules. By integrating tablets within capsules, the THDP machine offers a convenient and efficient way to administer multiple medications simultaneously, catering to patient needs for personalized treatment regimens.

The evolution of pharmaceutical machinery has brought about significant advancements in terms of automation, accuracy, and output capacity. Modern table press machines and capsule filling machines are equipped with cutting-edge technologies such as touch screen interfaces, automatic feeding systems, and real-time monitoring capabilities. These features not only enhance the efficiency of production processes but also ensure the uniformity and quality of the final pharmaceutical products.

In conclusion, the continuous advancement of pharmaceutical machinery, including table press machines and capsule filling machines such as the TDP and THDP, plays a pivotal role in revolutionizing the pharmaceutical industry. By improving production efficiency, ensuring product quality, and meeting the demands for personalized medication solutions, these innovative machines contribute to the overall growth and success of the pharmaceutical sector. As technology continues to progress, the future of pharmaceutical machinery holds even greater potential for shaping the landscape of medicine production and patient care.

Title: “The Evolution of Pharmaceutical Machinery: A Journey of Innovation and Efficiency”

Title: “The Evolution of Pharmaceutical Machinery: A Journey of Innovation and Efficiency” Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing” Title: “Revolutionizing Pharmaceutical Manufacturing with Advanced Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing with Advanced Pharmaceutical Machinery” Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery Title: The Evolution of Pharmaceutical Machinery: Advancements, Applications, and Future Trends

Title: The Evolution of Pharmaceutical Machinery: Advancements, Applications, and Future Trends Title: The Advancements of Pharmaceutical Machinery in the 21st Century

Title: The Advancements of Pharmaceutical Machinery in the 21st Century Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery” Title: The Evolution of Pharmaceutical Machinery: Improving Efficiency and Quality in Drug Manufacturing

Title: The Evolution of Pharmaceutical Machinery: Improving Efficiency and Quality in Drug Manufacturing Title: The Role of Pharmaceutical Machinery in Modern Healthcare

Title: The Role of Pharmaceutical Machinery in Modern Healthcare