Title: The Role of Pharmaceutical Machinery in the Manufacturing Process

Title: The Role of Pharmaceutical Machinery in the Manufacturing Process

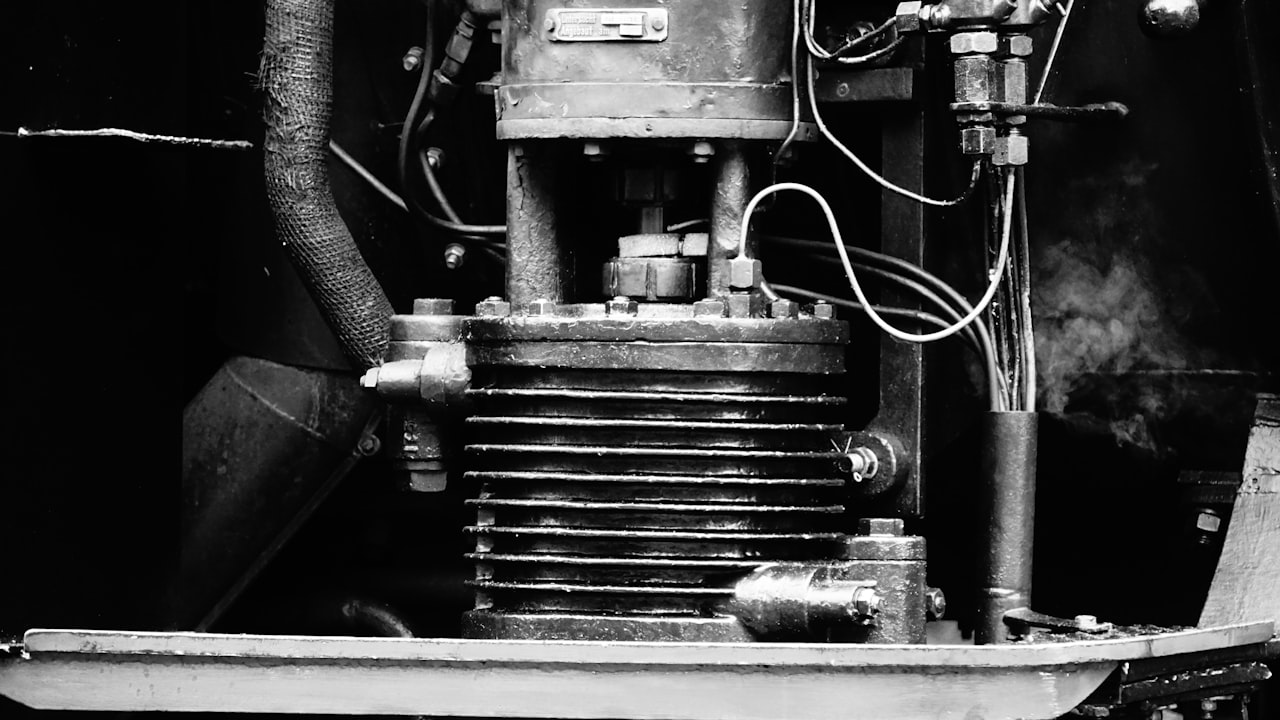

Pharmaceutical machinery plays a crucial role in the manufacturing process of medications. Among the various types of machinery used in pharmaceutical production, table press machines and capsule filling machines are two key components that contribute significantly to the efficiency and quality of the final product.

Table press machines, such as the TDP (Tablet Press) and THDP (Tablet Hardness Tester) machines, are essential for the compression of powdered ingredients into solid tablets. These machines utilize a combination of pressure and mechanical force to compact the ingredients into the desired shape and size. The TDP machine, in particular, plays a vital role in the tablet manufacturing process by ensuring uniform weight and dosage of each tablet. It is crucial for pharmaceutical companies to invest in high-quality table press machines to achieve consistent tablet quality and meet regulatory standards.

On the other hand, capsule filling machines are used to fill empty capsule shells with powdered or granular medication. These machines are designed to accurately fill the capsules with the correct dosage of the active pharmaceutical ingredient. Capsule filling machines come in various types, including manual, semi-automatic, and fully automatic machines. The efficiency and accuracy of these machines are crucial for ensuring precise dosing and reducing potential errors in the production process.

In addition to table press and capsule filling machines, other pharmaceutical machinery such as mixers, granulators, and coating machines also play integral roles in the manufacturing process. Mixers are used to blend different powder ingredients uniformly, while granulators help to form granules from powder mixtures for easier compression into tablets. Coating machines are used to apply a protective or functional coating to tablets or capsules to improve stability, appearance, or taste.

Overall, pharmaceutical machinery is essential for maintaining the quality, safety, and efficiency of pharmaceutical production. Investing in high-quality machinery not only ensures compliance with regulatory standards but also enhances the overall manufacturing process. Pharmaceutical companies must prioritize the selection and maintenance of their machinery to optimize production output and ensure the consistent delivery of high-quality medications to consumers.

Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing the Pharmaceutical Industry: The Role of Pharmaceutical Machinery” Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing” Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Drug Manufacturing” Title: The Ultimate Guide to Pharmaceutical Machinery: Types and Functions

Title: The Ultimate Guide to Pharmaceutical Machinery: Types and Functions Title: The Role of Pharmaceutical Machinery in Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Drug Manufacturing Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery” Title:

Title: