Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery

In the world of pharmaceutical manufacturing, the efficient production of high-quality drugs is crucial for the health and well-being of millions of people worldwide. One of the key factors contributing to this efficiency is the use of advanced pharmaceutical machinery. In this article, we will explore the significance of table press machines and capsule filling machines, with a particular focus on the TDP and THDP models.

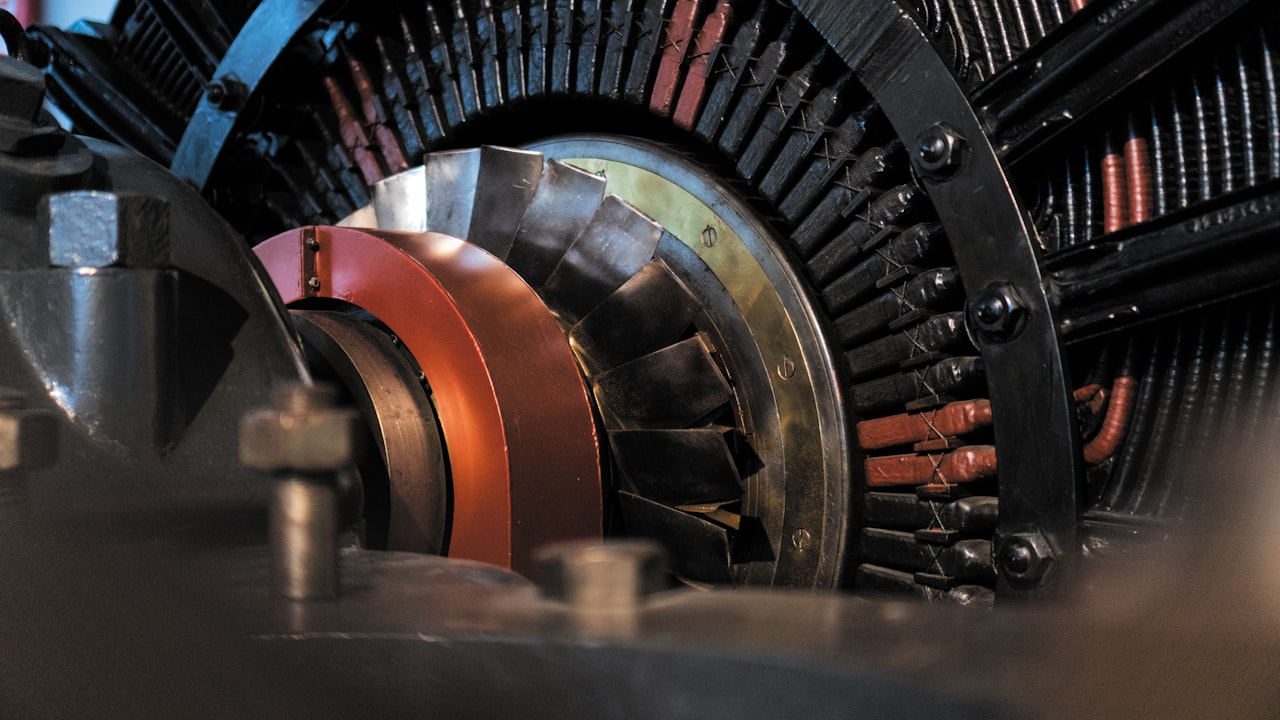

Tablet press machines, also known as tableting machines, play a vital role in the pharmaceutical industry by converting powders into compact tablets of precise weight and size. The TDP (Tablet Press) machine is a popular choice among pharmaceutical manufacturers due to its versatility and reliability. This machine utilizes a combination of compression and punch-die systems to form tablets with consistent quality and uniformity. With its advanced features such as adjustable compression force and speed control, the TDP machine offers pharmaceutical companies the flexibility to produce a wide range of tablet formulations efficiently.

On the other hand, capsule filling machines are essential for encapsulating powdered or granulated medications into gelatin or vegetarian capsules. The THDP (Hard Capsule Tablet Press) machine is a cutting-edge innovation that combines the functions of tablet pressing and capsule filling in a single compact unit. This hybrid machine allows pharmaceutical companies to streamline their production processes and optimize space utilization in their manufacturing facilities. By integrating tablet pressing and capsule filling capabilities, the THDP machine provides a cost-effective solution for pharmaceutical companies looking to enhance their production efficiency.

Overall, the use of advanced pharmaceutical machinery such as table press machines and capsule filling machines, including the TDP and THDP models, is revolutionizing the way drugs are manufactured. These sophisticated machines not only improve production speed and accuracy but also ensure the consistent quality of pharmaceutical products. As the pharmaceutical industry continues to evolve, investing in state-of-the-art machinery is essential for companies to stay competitive and meet the growing demands of the global market.

In conclusion, the role of pharmaceutical machinery in revolutionizing pharmaceutical manufacturing cannot be overstated. The efficiency and precision provided by table press machines and capsule filling machines, particularly the TDP and THDP models, are driving innovation and setting new standards in the industry. With the continuous advancement of technology, pharmaceutical companies can expect even more groundbreaking developments in machinery that will further enhance drug production processes and ultimately benefit patients worldwide.

Title: The Evolution of Pharmaceutical Machinery: Innovations Shaping the Future of Drug Manufacturing

Title: The Evolution of Pharmaceutical Machinery: Innovations Shaping the Future of Drug Manufacturing Title: “Revolutionizing Healthcare: The Role of Pharmaceutical Machinery in Modern Medicine”

Title: “Revolutionizing Healthcare: The Role of Pharmaceutical Machinery in Modern Medicine” Title: The Role of Pharmaceutical Machinery in the Manufacturing Process

Title: The Role of Pharmaceutical Machinery in the Manufacturing Process Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Title: Revolutionizing Medicine Production: A Closer Look at Pharmaceutical Machinery

Title: Revolutionizing Medicine Production: A Closer Look at Pharmaceutical Machinery Title: “The Advancements and Importance of Pharmaceutical Machinery”

Title: “The Advancements and Importance of Pharmaceutical Machinery” Title: “The Evolution of Pharmaceutical Machinery: A Comprehensive Overview”

Title: “The Evolution of Pharmaceutical Machinery: A Comprehensive Overview” Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in the Modern Era”

Title: “Revolutionizing Pharmaceutical Production: The Role of Pharmaceutical Machinery in the Modern Era” Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”