Title: “The Evolution of Pharmaceutical Machinery: Advancements in Drug Manufacturing Technology”

Title: “The Evolution of Pharmaceutical Machinery: Advancements in Drug Manufacturing Technology”

Pharmaceutical machinery has undergone significant evolution in recent years, revolutionizing the way drugs are manufactured. Key advancements in this field include the development of table press machines, capsule filling machines, TDP (Tablet Press) machines, and THDP (Tablet Hardness Testing) machines. These technological innovations have greatly improved the efficiency, precision, and quality of drug production processes.

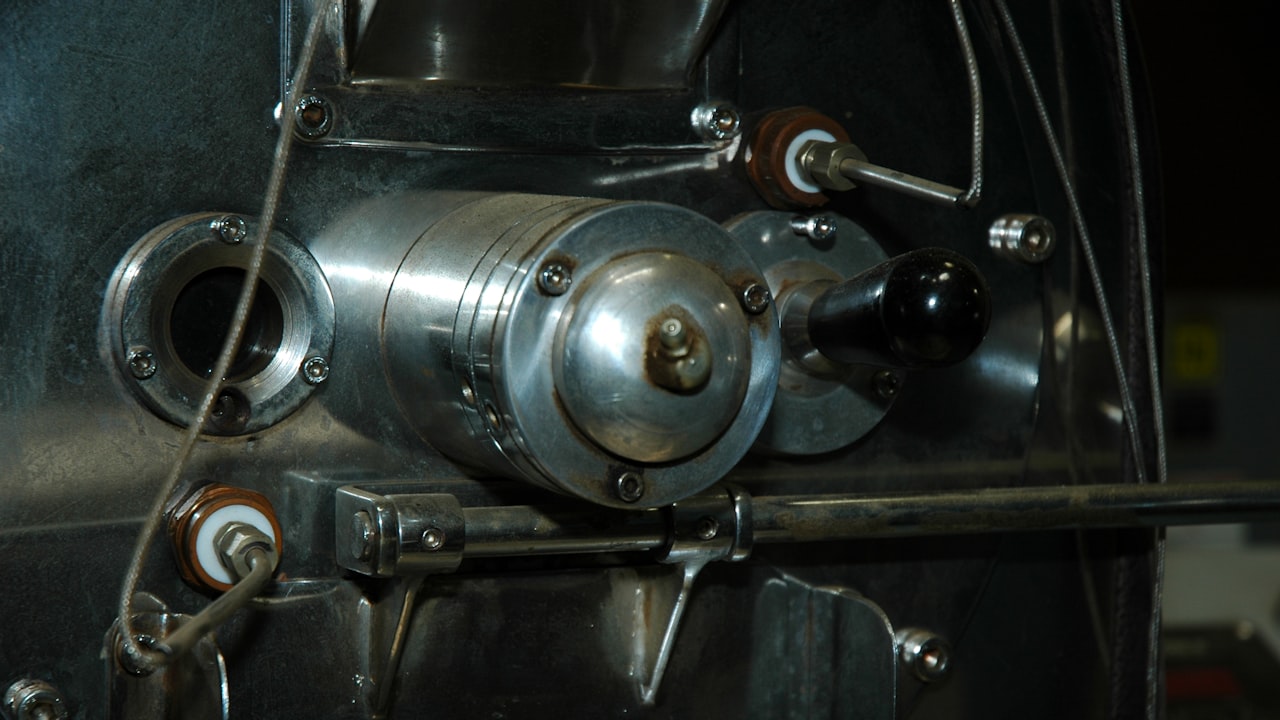

Table press machines play a crucial role in the pharmaceutical industry by compressing powdered ingredients into solid tablets. These machines have evolved over time to become more automated and sophisticated, with features such as adjustable compression force and speed control. This allows for greater flexibility in producing tablets of various sizes, shapes, and compositions with high accuracy and consistency.

Similarly, capsule filling machines have seen significant advancements in technology, enabling pharmaceutical companies to efficiently fill empty capsules with precise quantities of active ingredients. Modern capsule filling machines can handle a wide range of capsule sizes and formulations, increasing production capacity and reducing the risk of human error in the filling process.

TDP machines, also known as Tablet Press machines, are essential for the mass production of tablets in the pharmaceutical industry. These machines have evolved to incorporate innovative features such as automatic feeding systems, real-time monitoring of compression force, and quick changeover capabilities for different tablet designs. TDP machines ensure high-speed production while maintaining the quality and uniformity of the tablets.

In addition to manufacturing, quality control is a critical aspect of pharmaceutical production. THDP machines are used to assess the hardness and mechanical strength of tablets, ensuring they meet regulatory standards and provide consistent performance. These machines have advanced to offer precise and reliable testing methods, enhancing the overall quality assurance process in drug manufacturing.

Overall, the evolution of pharmaceutical machinery, including table press machines, capsule filling machines, TDP machines, and THDP machines, has revolutionized the drug manufacturing process. These technological advancements have resulted in increased efficiency, accuracy, and quality control in pharmaceutical production, leading to the development of safer and more effective medications for patients worldwide. As technology continues to advance, the future of pharmaceutical machinery holds even greater potential for innovation and improvement in drug manufacturing processes.

Title: The Impact of Pharmaceutical Machinery on Drug Production Efficiency

Title: The Impact of Pharmaceutical Machinery on Drug Production Efficiency Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery” Title: The Role of Pharmaceutical Machinery in Drug Manufacturing

Title: The Role of Pharmaceutical Machinery in Drug Manufacturing Title: “The Advancements of Pharmaceutical Machinery in Modern Healthcare”

Title: “The Advancements of Pharmaceutical Machinery in Modern Healthcare” Title: “Innovations in Pharmaceutical Machinery: Revolutionizing Drug Manufacturing Processes”

Title: “Innovations in Pharmaceutical Machinery: Revolutionizing Drug Manufacturing Processes” Title: “The Evolution of Pharmaceutical Machinery: Innovations and Advancements in Drug Manufacturing”

Title: “The Evolution of Pharmaceutical Machinery: Innovations and Advancements in Drug Manufacturing” Title: The Impact of Pharmaceutical Machinery on Modern Medicine

Title: The Impact of Pharmaceutical Machinery on Modern Medicine Title: “Revolutionizing Medicine Production: A Comprehensive Guide to Pharmaceutical Machinery”

Title: “Revolutionizing Medicine Production: A Comprehensive Guide to Pharmaceutical Machinery” Title: The Cutting-edge Technology of Pharmaceutical Machinery: Revolutionizing the Drug Manufacturing Industry

Title: The Cutting-edge Technology of Pharmaceutical Machinery: Revolutionizing the Drug Manufacturing Industry