Title: “The Role of Pharmaceutical Machinery in Drug Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Drug Manufacturing”

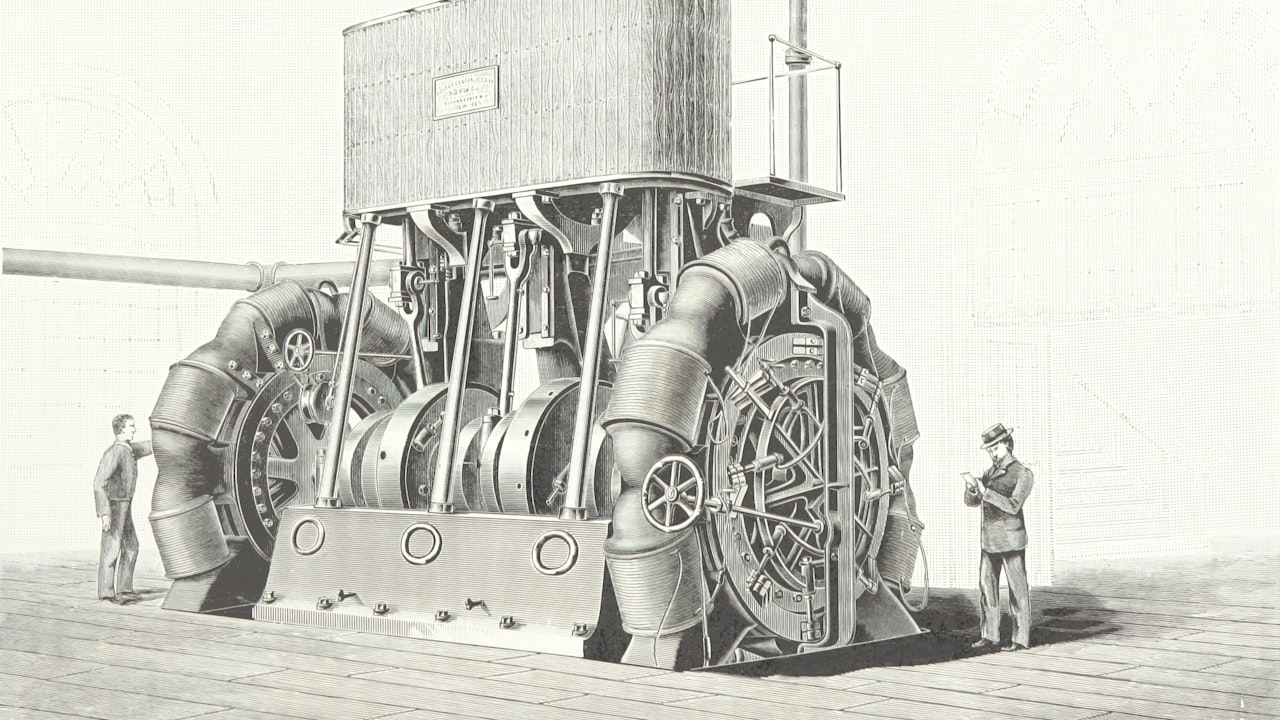

Pharmaceutical machinery plays a crucial role in the manufacturing process of drugs, ensuring efficiency and precision in the production of pharmaceutical products. Among the key machinery used in drug manufacturing are the table press machine, capsule filling machine, TDP (Tablet Press Machine), and THDP (Tablet Hardness Tester).

The table press machine is an essential piece of equipment in pharmaceutical manufacturing, used to compress powder formulations into tablets of specific shapes and sizes. By applying controlled pressure, the table press machine effectively consolidates the powder blend to form solid tablets that meet the required quality standards. This process is critical in ensuring the uniformity and consistency of each tablet produced.

On the other hand, the capsule filling machine is designed to accurately fill empty gelatin or vegetable capsules with the desired amount of powdered, granulated, or liquid medication. This automated machine ensures precise dosing and uniform filling of capsules, minimizing variations in dosage and enhancing the efficiency of the manufacturing process. By automating the filling process, the capsule filling machine helps pharmaceutical companies streamline production and maintain high-quality standards.

In pharmaceutical manufacturing, the TDP (Tablet Press Machine) is widely used for tablet compression, allowing for the production of large quantities of tablets in a relatively short period. This machine utilizes mechanical or hydraulic pressure to compress powdered ingredients into tablets of uniform size and weight. The TDP is versatile and can accommodate various tablet shapes and sizes, making it suitable for a wide range of pharmaceutical formulations.

Furthermore, the THDP (Tablet Hardness Tester) is an important quality control equipment used to measure the hardness and integrity of tablets. This machine applies a controlled amount of force to the tablets to assess their resistance to breakage or crumbling. By evaluating the hardness of tablets, pharmaceutical companies can ensure the durability and stability of the product, which is crucial for maintaining product quality and patient safety.

In conclusion, pharmaceutical machinery such as the table press machine, capsule filling machine, TDP, and THDP play a vital role in drug manufacturing by ensuring precision, efficiency, and quality control throughout the production process. These advanced machines not only streamline production but also contribute to the consistent and reliable manufacturing of pharmaceutical products that meet regulatory standards and patient needs.

Title: The Evolution of Pharmaceutical Machinery in Modern Medicine

Title: The Evolution of Pharmaceutical Machinery in Modern Medicine Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery in Modern Medicine

Title: Revolutionizing Pharmaceutical Manufacturing: The Role of Pharmaceutical Machinery in Modern Medicine Title: “The Advancements in Pharmaceutical Machinery: Revolutionizing Drug Production”

Title: “The Advancements in Pharmaceutical Machinery: Revolutionizing Drug Production” Title: “The Role of Pharmaceutical Machinery in Modern Healthcare Industry”

Title: “The Role of Pharmaceutical Machinery in Modern Healthcare Industry” The Role of Pharmaceutical Machinery in Modern Drug Manufacturing

The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes

Title: The Role of Pharmaceutical Machinery in Modern Drug Manufacturing Processes Title: “Revolutionizing Drug Production: The Role of Pharmaceutical Machinery”

Title: “Revolutionizing Drug Production: The Role of Pharmaceutical Machinery” Title: “The Evolution of Pharmaceutical Machinery: Innovations and Impact”

Title: “The Evolution of Pharmaceutical Machinery: Innovations and Impact” Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”

Title: “The Role of Pharmaceutical Machinery in Modern Medicine Manufacturing”