Title: The Evolution of Pharmaceutical Machinery: Improving Efficiency and Quality in Drug Manufacturing

Title: The Evolution of Pharmaceutical Machinery: Improving Efficiency and Quality in Drug Manufacturing

In the ever-evolving landscape of the pharmaceutical industry, technological advancements in machinery have played a pivotal role in enhancing the efficiency and quality of drug manufacturing processes. Among the key pieces of equipment driving this progress are table press machines and capsule filling machines, such as the TDP (Tablet Press) and THDP (Tablet Hardness Tester).

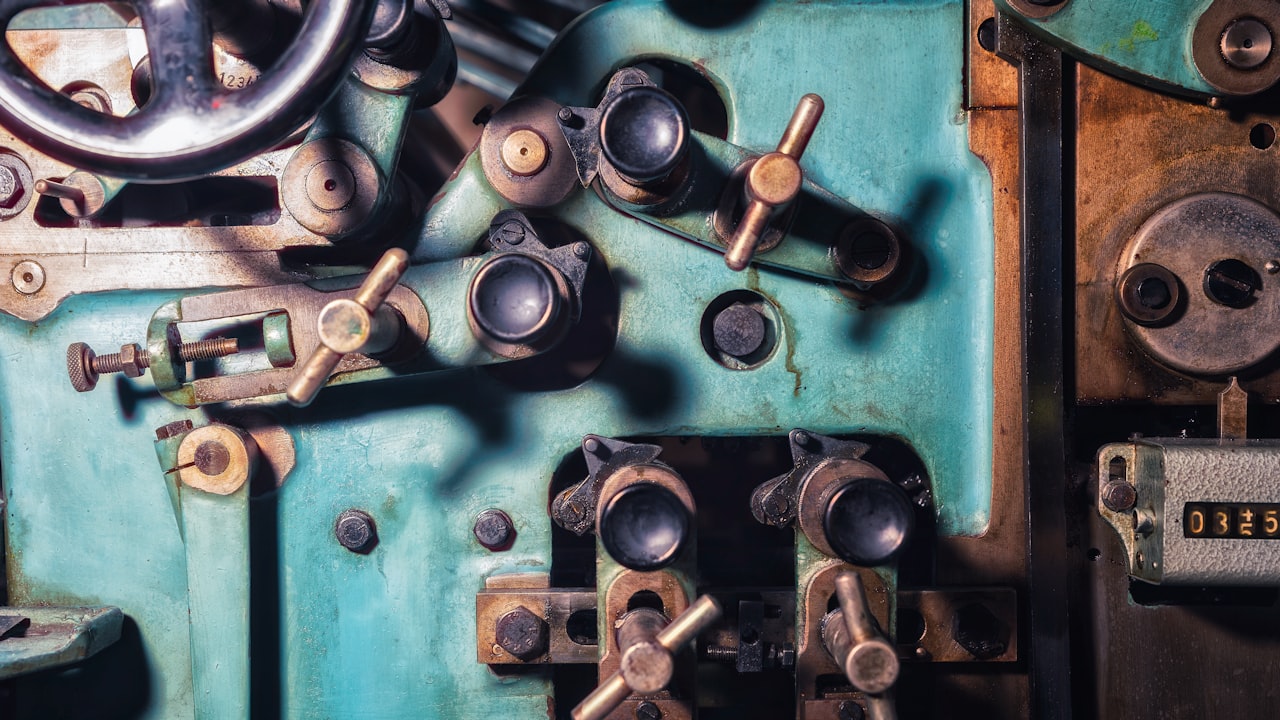

Table press machines, commonly known as tablet presses, are essential in the pharmaceutical manufacturing process for producing tablets of various shapes, sizes, and compositions. These machines work by compressing powdered ingredients or granules into solid dosage forms that are easy to administer to patients. The evolution of table press machines has seen significant improvements in terms of speed, precision, and automation, allowing pharmaceutical companies to increase their production capacity and maintain consistent tablet quality.

Similarly, capsule filling machines have revolutionized the way medications are encapsulated and delivered to patients. These machines utilize different mechanisms, such as dosators or tamping systems, to accurately fill empty capsules with the desired dose of powdered or granular medication. The development of advanced capsule filling machines has led to higher production speeds, improved dosing accuracy, and enhanced versatility in handling a wide range of formulations.

One of the noteworthy advancements in table press machines is the introduction of the TDP series, which are compact and efficient tablet presses ideal for small to mid-scale pharmaceutical manufacturers. The TDP machines offer features such as adjustable tablet thickness and weight control, making them versatile for producing various types of tablets with consistent quality. Moreover, the integration of automation and digital controls in TDP machines has minimized manual intervention, reducing the risk of human error and ensuring a higher level of production efficiency.

On the other hand, the THDP, or Tablet Hardness Tester, has emerged as a critical tool for pharmaceutical companies to assess the mechanical strength and integrity of tablets. By measuring the hardness and friability of tablets, the THDP helps manufacturers evaluate the quality and durability of their products, ensuring that they meet regulatory standards and are safe for consumption. The integration of THDP machines in the production process enables real-time monitoring of tablet hardness, allowing manufacturers to make timely adjustments and maintain consistent product quality.

In conclusion, the evolution of pharmaceutical machinery, particularly table press machines and capsule filling machines like the TDP and THDP, has significantly contributed to improving the efficiency and quality of drug manufacturing. These technological innovations have not only enhanced production processes but also enabled pharmaceutical companies to meet the increasing demands for safe and effective medications in a competitive market. As the pharmaceutical industry continues to advance, the continual improvement of machinery will be crucial in driving innovation and ensuring the development of high-quality pharmaceutical products for the benefit of patients worldwide.