Title: “Revolutionizing the Pharmaceutical Industry: The Impact of Pharmaceutical Machines”

Title: “Revolutionizing the Pharmaceutical Industry: The Impact of Pharmaceutical Machines”

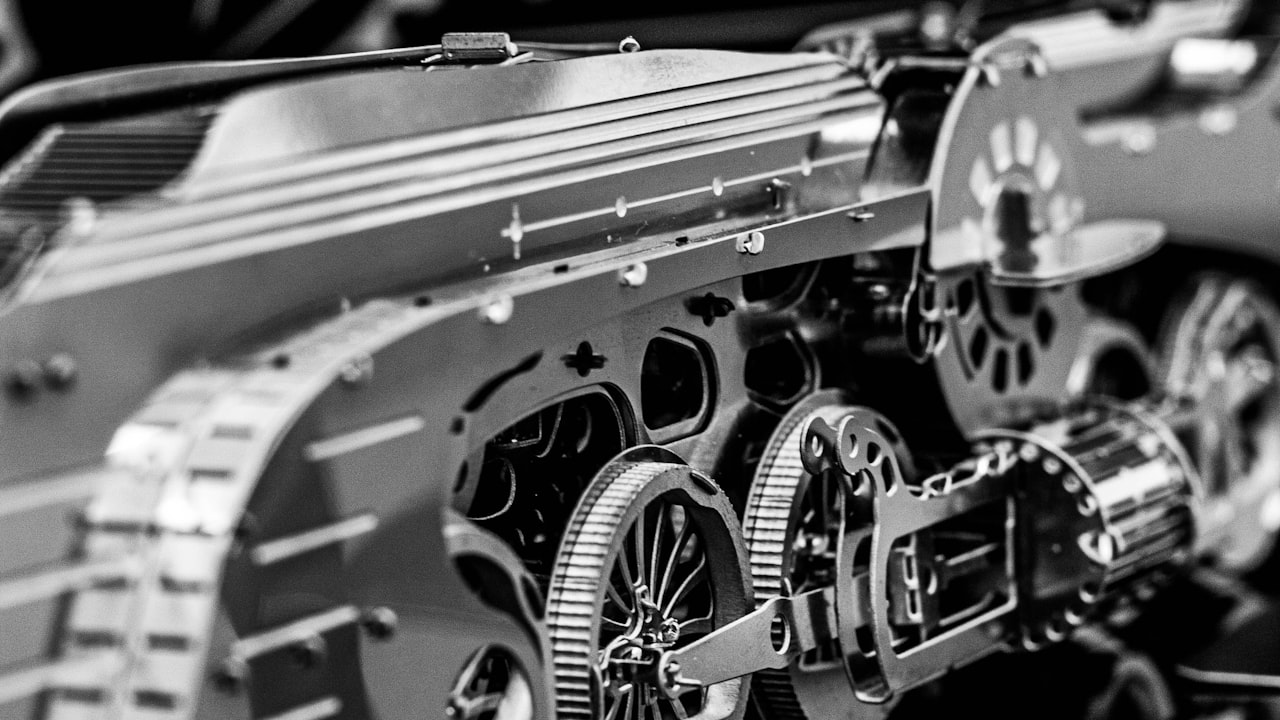

In today’s rapidly evolving pharmaceutical industry, the role of pharmaceutical machines cannot be overstated. These advanced machines, such as table press machines and capsule filling machines, have revolutionized the way medicines are manufactured, improving efficiency, accuracy, and consistency in drug production. Among these machines, the TDP (Tablet Press) and THDP (Tablet and Capsule Press) machines stand out as key players in shaping the future of pharmaceutical manufacturing.

Table press machines, including the popular TDP series, are essential for producing tablets of various shapes and sizes. These machines operate by compressing powdered ingredients into solid doses. With precise control over parameters such as compression force and tablet thickness, table press machines ensure uniformity in tablet quality, making them indispensable for pharmaceutical companies striving to meet strict regulatory standards.

Capsule filling machines, on the other hand, such as the THDP series, automate the process of filling capsules with precise amounts of powdered or granulated medication. These machines not only enhance production efficiency but also reduce the risk of human error, ensuring accurate dosing in each capsule. By streamlining the capsule filling process, THDP machines enable pharmaceutical manufacturers to meet the growing demand for dosage forms that provide convenience and consistency to patients.

The introduction of TDP and THDP machines has brought significant benefits to the pharmaceutical industry. These machines have increased production speed, lowered production costs, and improved product quality compared to traditional manual methods. Moreover, they offer flexibility in manufacturing, allowing for quick changeovers between different tablet or capsule formulations, thereby enhancing operational efficiency.

In addition to operational advantages, pharmaceutical machines like TDP and THDP play a crucial role in ensuring drug safety and efficacy. By maintaining strict control over the manufacturing process, these machines reduce the risk of contamination, dosage variability, and inconsistent drug release profiles. Ultimately, the use of advanced pharmaceutical machines contributes to the development of high-quality, reliable medications that meet regulatory requirements and patient needs.

As technology continues to advance, the pharmaceutical industry will undoubtedly see further innovations in pharmaceutical machines. From enhanced automation and integration with data analytics to the development of smart machines capable of self-adjustment, the future of pharmaceutical manufacturing holds exciting possibilities. The ongoing evolution of pharmaceutical machines will continue to drive efficiency, quality, and innovation in drug production, ultimately benefiting both pharmaceutical companies and patients worldwide.

In conclusion, the impact of pharmaceutical machines, including table press machines like the TDP series and capsule filling machines like the THDP series, cannot be underestimated. These advanced machines have transformed pharmaceutical manufacturing, setting new standards for efficiency, accuracy, and quality in drug production. As the pharmaceutical industry continues to evolve, the role of pharmaceutical machines will remain pivotal in driving progress and innovation in drug development and manufacturing processes.